Electroplated Diamond Balls

Electroplated Diamond Balls | Braemar USA

Braemar USA’s Electroplated Diamond Balls are precision tools engineered for micro-grinding and fine-finishing applications. Crafted with a single layer of premium synthetic diamond, bonded with a nickel electroplated matrix, these tools deliver exceptional sharpness, form accuracy, and surface quality. As a result, they are ideal for machining some of the world’s hardest and most brittle materials. Therefore, they provide maximum performance, particularly in highly demanding machining environments. In addition, their superior quality ensures outstanding durability, even under the most challenging conditions. Not only do they provide excellent results, but their reliability guarantees consistent performance throughout their use, no matter the complexity of the task.

Key Features:

-

Single-Layer Diamond Coating: This feature maximizes sharpness, ensuring aggressive cutting action and longer tool life. Moreover, the coating allows for efficient grinding with minimal wear, thus increasing the longevity of the tools. Additionally, it minimizes the maintenance required, which ultimately results in higher productivity.

-

True Spherical Geometry: Consequently, it guarantees consistent form accuracy, particularly in micro-grinding operations. Even with continuous use, the geometry remains precise and uniform, ensuring high-quality finishes. Therefore, you can rely on the tool for consistent, reliable results, which are crucial for maintaining the highest standards.

-

Nickel Matrix Bond: As a result, this bond provides strong diamond retention, ensuring stable tool performance over extended use. Moreover, it helps maintain cutting effectiveness during long production runs, leading to enhanced productivity and reduced downtime. Thus, the tool stays efficient for longer periods, maximizing value for the user. In turn, this results in reduced overall operational costs.

-

Customizable Options: Furthermore, these tools are available in a variety of diameters, shank sizes, grit sizes, and coating exposure options, allowing for tailored solutions to meet your specific needs. In fact, this flexibility ensures you get the perfect tool for every job, regardless of complexity or material type. As a result, you achieve optimal precision and performance for various tasks.

-

Designed for Hard, Brittle Materials: Therefore, these tools are perfectly suited for use with ceramics, carbide, sapphire, quartz, glass, and advanced optical or semiconductor materials. This versatility makes them highly adaptable to a wide range of high-precision applications. In addition, this adaptability ensures you can use them for different tasks, expanding their utility across industries.

Applications:

Braemar Electroplated Diamond Balls excel in several key applications, including:

-

Optical Lens and Mold Fabrication

-

Micro-Contour Grinding: Specifically, these tools are highly effective when working with materials like sapphire, quartz, and glass, providing accurate and reliable finishes. Thus, they are ideal for producing fine, detailed features with precision, which is essential for industries requiring the highest standards.

-

Ceramic Micro-Machining

-

Carbide Die and Mold Finishing

-

Semiconductor Wafer Edge Finishing

-

Micro-Deburring and tool & die repair

-

3D Surface Treatment in precision manufacturing

Industries Served:

These tools are trusted across various industries, including:

-

Optical Manufacturing

-

Semiconductor Processing

-

Medical Device Machining

-

Aerospace Component Finishing

-

Advanced Materials Research

-

Carbide Tool & Die Production

-

Electronics and Micro-Component Manufacturing

Why Choose Braemar USA Electroplated Diamond Balls?

Braemar USA is committed to providing electroplated diamond tools that meet the highest quality standards. Our products are recognized for:

-

Plating Consistency: This ensures long-lasting, reliable performance over time. Moreover, the uniform plating helps maintain sharpness and efficiency, resulting in more consistent results throughout the tool’s life. Additionally, this consistency improves the overall durability of the tool, which makes it a worthwhile investment for long-term use.

-

Precise Diamond Exposure: Thanks to precise diamond exposure, cutting efficiency is enhanced and tool life is extended. Furthermore, it minimizes wear during operation, which ultimately translates to lower maintenance costs and higher productivity. Thus, users benefit from reduced downtime and fewer tool replacements, thereby improving operational efficiency and profitability.

-

Low-Temperature Plating: This process prevents nickel from climbing over the diamond edges, ensuring that the cutting surface remains sharp and effective throughout its use. In turn, this prolongs the life and performance of the tool. Consequently, the tools deliver consistent results throughout their lifespan, making them a cost-effective solution for demanding applications.

Whether you need standard sizes or custom-engineered solutions, Braemar USA delivers precision tools for your most demanding machining tasks. In conclusion, our tools provide the reliability and performance required for high-precision applications, ensuring optimal results every time. Therefore, you can trust Braemar USA to meet your most challenging machining requirements.

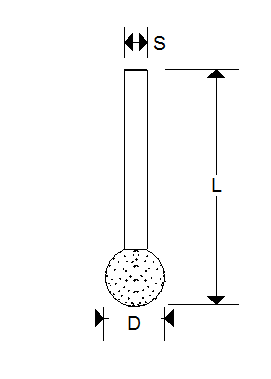

Common Sizes & Specifications:

-

Diameters: 0.040″ to 1.000″

-

Shank Sizes: 1/8″ or 1/4″

-

Grit Sizes: 40–600 mesh (from coarse to ultra-fine)

-

Coating Coverage: Full ball for uniform and consistent cutting action

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

ITEM#

DPBSS045A

DPBSS060A

DPBSS060B

DPB062

DPBSS078A

DPB080

DPBSS087A

DPBSS093A

DPBSS125A

DPB156

DPB187

DPBSS200A

DPBSS230A

DPBSS250A

DPBSS255A

DPBSS290A

DPBSS290B

DPBSS315A

DPBSS324A

DPBSS375A

DPB50012

DPBSS539A

DPBSS750A

DPB750-100

D

0.045

0.060

0.060

0.062

0.078

0.080

0.087

0.093

0.125

0.156

0.187

0.200

0.230

0.250

0.255

0.290

0.290

0.315

0.324

0.375

0.500

0.539

0.750

0.750

S

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.125

0.250

0.125

0.250

0.125

0.125

0.125

0.250

0.125

0.250

0.250

0.250

0.250

L

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

2.000

GRIT

200/220

140/170

170/200

100/120

100/120

100/120

200/220

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

060/080

100/120

100/120

080/100

100/120

100/120

080/100

080/100

100/120

ITEM#:

DPBSS045A

D:

0.045

S:

0.125

L:

2.000

GRIT:

200/220

ITEM#:

DPBSS060A

D:

0.060

S:

0.125

L:

2.000

GRIT:

140/170

ITEM#:

DPBSS060B

D:

0.060

S:

0.125

L:

2.000

GRIT:

170/200

ITEM#:

DPB062

D:

0.062

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS078A

D:

0.078

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPB080

D:

0.080

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS087A

D:

0.087

S:

0.125

L:

2.000

GRIT:

200/220

ITEM#:

DPBSS093A

D:

0.093

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS125A

D:

0.125

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPB156

D:

0.156

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPB187

D:

0.187

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS200A

D:

0.200

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS230A

D:

0.230

S:

0.250

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS250A

D:

0.250

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS255A

D:

0.255

S:

0.250

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS290A

D:

0.290

S:

0.125

L:

2.000

GRIT:

060/080

ITEM#:

DPBSS290B

D:

0.290

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS315A

D:

0.315

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS324A

D:

0.324

S:

0.250

L:

2.000

GRIT:

080/100

ITEM#:

DPBSS375A

D:

0.375

S:

0.125

L:

2.000

GRIT:

100/120

ITEM#:

DPB50012

D:

0.500

S:

0.250

L:

2.000

GRIT:

100/120

ITEM#:

DPBSS539A

D:

0.539

S:

0.250

L:

2.000

GRIT:

080/100

ITEM#:

DPBSS750A

D:

0.750

S:

0.250

L:

2.000

GRIT:

080/100

ITEM#:

DPB750-100

D:

0.750

S:

0.250

L:

2.000

GRIT:

100/120