Metal Bond Diamond Beveling Wheels

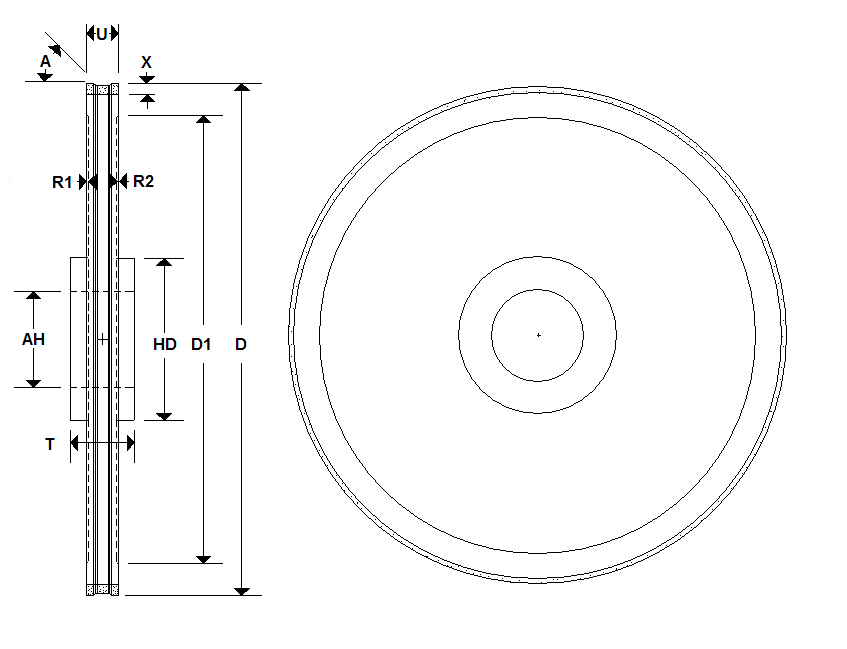

Metal bond diamond beveling wheels deliver precise edge beveling, chamfering, and edge conditioning for optical components. A sintered metal bond matrix firmly holds the diamond abrasive. As a result, the wheel maintains stable geometry, resists wear, and performs consistently during long production runs. This stability helps operators achieve repeatable bevel angles and clean edges.

These wheels process optical glass, fused silica, quartz, sapphire, and advanced ceramics with excellent edge control. Therefore, they reduce chipping on brittle materials and protect thin or fragile substrates. In addition, the durable metal bond structure extends wheel life and significantly lowers dressing frequency compared to resin bond wheels. This improvement increases machine uptime and process efficiency.

Manufacturers use these wheels for lens edge beveling, safety chamfers, prism shaping, and pre-polish edge preparation. Operators run them on both CNC and manual optical grinding systems. Multiple grit sizes, bond hardness levels, and diamond concentrations allow precise tuning for specific materials and machine conditions.

Furthermore, customers can select solid rims, segmented designs, or integrated coolant channels to improve heat control and swarf removal. Overall, metal bond diamond beveling wheels provide reliable cutting performance, consistent edge geometry, and predictable results for downstream polishing operations.

Call (480) 966-9311 or Add to Quote for pricing.