1EE1 Diamond Wheels

1EE1 Diamond Wheels are engineered for high-precision grinding applications that require accurate slotting, edge forming, and controlled material removal on carbide, ceramics, glass, quartz, sapphire, and other advanced materials. The 1EE1 wheel shape features a reinforced hub design with a precision-formed abrasive rim—ideal for producing sharp, consistent profiles and ultra-clean groove geometries.

Manufactured with premium synthetic diamond and Braemar’s engineered resin bond systems, these wheels provide a cool-cutting, low-force grind that protects delicate materials from chipping, burning, and micro-fracture. The resin matrix offers controlled breakdown, ensuring continuous exposure of sharp diamond particles for excellent surface finish and long-term performance in demanding production environments.

1EE1 Wheel Shape Features

-

Reinforced hub with precision outer rim

-

Ideal for slotting, forming, grooving, and edge-prep operations

-

Excellent rigidity for maintaining profile accuracy

-

Ideal for CNC tool grinding and automated setups

-

Supports tight-tolerance finishing on carbide and technical ceramics

Resin Bond Advantages

-

Cool, free-cutting operation with reduced heat generation

-

Lower grinding forces for fragile or heat-sensitive materials

-

Consistent diamond exposure for stable performance

-

Superior surface finish compared to metal bond wheels

-

Reduced risk of cracking, burning, or material distortion

Applications

Braemar USA 1EE1 Resin Bond Diamond Wheels excel in:

-

Precision slot grinding

-

Forming carbide tools and inserts

-

Cutting grooves in ceramics and technical glass

-

Optical edge shaping

-

Quartz and sapphire machining

-

High-accuracy tool and die work

-

Semiconductor and electronics component finishing

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Why Choose Braemar USA?

Braemar USA combines precision engineering, advanced resin bond chemistry, and high-grade synthetic diamond to deliver wheels that maintain form accuracy, reduce downtime, and improve part consistency across your grinding operations. Every 1EE1 wheel is manufactured for reliability, repeatability, and long service life in modern production environments.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

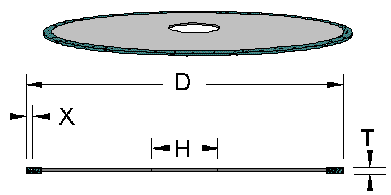

(D) WHEEL DIAMETER

3.000

3.000

4.000

4.000

6.000

6.000

7.000

(T) WHEEL WIDTH

0.125

0.250

0.125

0.250

0.125

0.250

0.250

(H) ARBOR HOLE

SPECIFY HOLE

SPECIFY HOLE

SPECIFY HOLE

SPECIFY HOLE

SPECIFY HOLE

SPECIFY HOLE

SPECIFY HOLE

GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

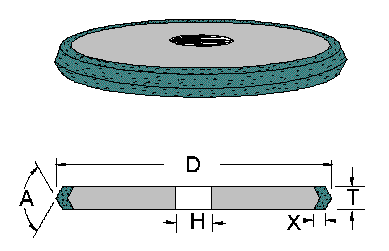

(A) INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

3.000

(T) WHEEL WIDTH:

0.125

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

3.000

(T) WHEEL WIDTH:

0.250

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

4.000

(T) WHEEL WIDTH:

0.125

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

4.000

(T) WHEEL WIDTH:

0.250

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

6.000

(T) WHEEL WIDTH:

0.125

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

6.000

(T) WHEEL WIDTH:

0.250

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE

(D) WHEEL DIAMETER:

7.000

(T) WHEEL WIDTH:

0.250

(H) ARBOR HOLE:

SPECIFY HOLE

GRIT SIZE:

SPECIFY GRIT SIZE

(A) INCLUDED ANGLE:

SPECIFY INCLUDED ANGLE