11A2 Diamond Wheels

Precision Dish Geometry for Controlled Grinding

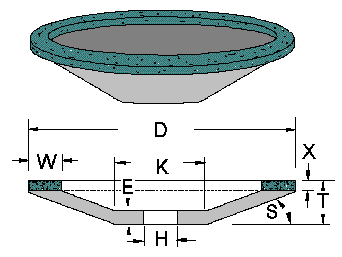

11A2 Diamond Wheels from Braemar USA are engineered for applications that require strict geometry control, thermal stability, and consistent abrasive performance. The wheel uses a dish-shaped profile with a defined slant angle. This structure improves access to cutting edges, fluting surfaces, and complex relief features. Because the geometry reduces side interference, operators reach detailed tool forms with greater stability. In addition, the wheel holds a steady cutting plane during long grinding cycles, so dimensional accuracy stays predictable.

Thermal Management and Form Stability

The 11A2 profile supports controlled grinding on carbide, ceramics, glass, and advanced composites. Since the design lowers contact area, grinding forces remain reduced. Lower forces generate less heat, which helps protect brittle materials from micro-cracking and subsurface damage. Moreover, the wheel maintains excellent form stability. This behavior minimizes dimensional drift and supports repeatable performance in both tool-room and production environments.

Applications Across Cutting Tool Manufacturing

Engineers rely on 11A2 Diamond Wheels for sharpening and shaping end mills, drills, engraving tools, router bits, carbide inserts, and saw tips. The wheel also performs well in contouring and profile-grinding operations where clearance angles and relief geometry must be controlled. Resin-bond versions provide cool cutting and predictable self-sharpening due to steady diamond exposure. Metal-bond versions deliver higher rigidity and extended life under heavy loads or continuous-duty cycles.

Broad Machine Compatibility

The 11A2 configuration fits many grinding systems. CNC platforms such as Walter, ANCA, Rollomatic, Saacke, and EWAG commonly use this shape for flute relief, gashing, and edge preparation. Surface grinders from Harig, Okamoto, and Boyar-Schultz run 11A2 wheels with angle fixtures. Manual Deckel SO and SOE grinders also benefit from the wheel’s improved reach for small carbide tools.

Typical Specifications

Diameters typically range from 100 mm to 200 mm, with grit sizes from 80 to 600+. Dish angles of 20° or 30° allow tuning for roughing, semi-finishing, or precision finishing work. Consequently, 11A2 Diamond Wheels deliver stable performance, accurate geometry retention, and clean surfaces across demanding grinding operations.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

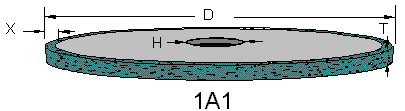

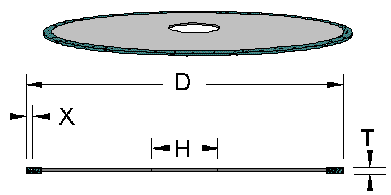

(D) DIAMETER

3.000"

3.500"

4.000"

5.000"

6.000"

7.000"

(T) WHEEL HEIGHT

0.875"

1.250"

1.250"

1.250"

1.500"

1.750"

(H) ARBOR HOLE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

SPECIFY GRIT SIZE

(W) RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

(D) DIAMETER:

3.000"

(T) WHEEL HEIGHT:

0.875"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(D) DIAMETER:

3.500"

(T) WHEEL HEIGHT:

1.250"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(D) DIAMETER:

4.000"

(T) WHEEL HEIGHT:

1.250"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(D) DIAMETER:

5.000"

(T) WHEEL HEIGHT:

1.250"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(D) DIAMETER:

6.000"

(T) WHEEL HEIGHT:

1.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(D) DIAMETER:

7.000"

(T) WHEEL HEIGHT:

1.750"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT SIZE

(W) RIM WIDTH:

SPECIFY RIM WIDTH