12A2 CBN Wheels

12A2 CBN Wheels Resin Bond are engineered for precision grinding applications that demand exceptional edge stability, cool-cutting performance, and superior surface finish on hardened steels and high-alloy materials. The 12A2 profile features a dish-shaped, reinforced structure that provides excellent rigidity and clearance—making it ideal for sharpening, tool room grinding, jig grinding, and profile grinding of ferrous materials.

Built with premium CBN abrasive and advanced resin bond matrices, Braemar 12A2 wheels deliver clean, fast cutting with reduced heat generation, minimal burning, and consistent form accuracy across long production runs.

Key Features & Performance Advantages

Optimized for Hardened Steels & High-Alloy Metals

CBN is the abrasive of choice for ferrous materials, delivering unmatched grinding efficiency on:

-

High-speed steel (HSS)

-

M2, M35, M42 cobalt steels

-

D2, A2, S7 tool steels

-

Powder-metal steels

-

Bearing steels (52100)

-

Heat-treated alloy steels

-

Nickel-based superalloys

Resin bond holds the CBN abrasive securely while providing controlled breakdown to expose new, sharp cutting edges.

Cool-Cutting Resin Bond Technology

Braemar’s resin bond system provides:

-

Lower grinding forces

-

Reduced heat and burning

-

Smoother cutting action

-

Longer wheel life in precision environments

-

Excellent surface finish with minimal micro-fracture

These characteristics make the 12A2 ideal for grinding delicate geometries and heat-sensitive tool edges.

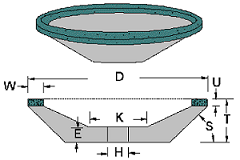

12A2 Wheel Shape Advantages

The distinctive 12A2 dish-style geometry offers:

-

Strong sidewall support

-

Increased tool clearance

-

Stable grinding of angles and profiles

-

Reliable form retention for repetitive tool making

-

Smooth, vibration-free operation

Perfect for tool sharpening, deburring, and precision form grinding.

Applications

Braemar 12A2 CBN resin bond wheels are commonly used for:

-

Tool & cutter sharpening

-

Jig grinding and fixture grinding

-

Profile grinding of hardened steels

-

Sharpening end mills, reamers, and form tools

-

Precision surface and edge grinding

-

CNC tool grinding operations

-

Grinding dies, punches, and wear components

Engineered for consistent, repeatable performance in production and tool room environments.

Why Choose Braemar USA CBN Wheels?

-

Premium CBN concentration for fast, clean cutting

-

Proven resin bond formulas for heat-controlled grinding

-

High form accuracy & stable geometry

-

Long wheel life with predictable performance

-

U.S. engineering support & custom specifications available

-

Ideal for both manual and CNC grinding systems

Call (480) 966-9311 or Add to Quote for pricing.