12A2 Diamond Wheels

Product Overview

Braemar USA’s 12A2 Resin Bond Diamond Wheels are designed for precision grinding of carbide, ceramics, glass, quartz, sapphire, and advanced technical materials. The 12A2 dish profile provides controlled access for edge shaping, relief angles, and complex geometries. In addition, the resin bond system supports cool-cutting, low-force grinding with predictable wear behavior.

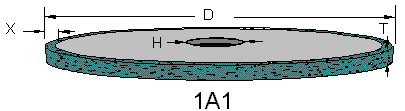

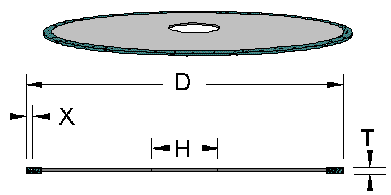

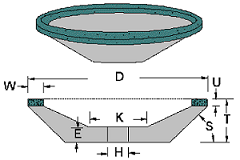

Wheel Geometry (12A2 Shape)

-

Dish-style profile with relieved center

-

Angled grinding rim for improved access

-

Rigid structure for tight tolerance applications

-

Supports end gash grinding, relief work, and profile shaping

Bond System – Resin Bond

-

Cool-cutting action for reduced heat

-

Lower grinding forces on brittle substrates

-

Controlled diamond exposure for self-sharpening

-

Stable surface finish across long grinding cycles

-

Reduced risk of burning or micro-cracking

Diamond & Abrasive Characteristics

-

Premium synthetic diamond

-

Uniform diamond distribution

-

Customizable grit sizes (60–2000 mesh)

-

Adjustable diamond concentration by request

-

Enhanced retention for consistent wear rates

Performance Characteristics

-

Maintains geometry under continuous load

-

Suitable for roughing and finishing passes

-

Predictable wheel life in production environments

-

Low vibration and smooth cutting behavior

-

Excellent corner stability for precision forms

Material Compatibility

-

Tungsten carbide

-

Technical ceramics (Al₂O₃, Si₃N₄, ZrO₂)

-

Sapphire and quartz

-

Fused silica and optical glass

-

Carbon and ceramic matrix composites

Typical Applications

-

End gash grinding

-

Tool relief and point thinning

-

Precision edge shaping

-

CNC carbide and ceramic tool grinding

-

Optical and semiconductor component processing

Available Specifications

-

Diameters: 75 mm–200 mm (custom sizes available)

-

Rim widths and angles: configurable per application

-

Arbor/ID sizes: standard and custom

-

Grit and concentration: full range options

-

Tolerances: engineered to customer requirements

Why Braemar USA

-

Precision bond formulations

-

Highly consistent manufacturing

-

Stable geometry across tool life

-

Fast customization for specialized processes

-

Proven performance in demanding grinding environments

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

(D) DIAMETER

3.000"

3.000"

4.000"

4.000"

6.000"

(T) WHEEL HEIGHT

0.500"

0.500"

0.500"

0.500"

0.500"

(H) ARBOR HOLE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

SPECIFY HOLE SIZE

GRIT SIZE

SPECIFY GRIT

SPECIFY GRIT

SPECIFY GRIT

SPECIFY GRIT

SPECIFY GRIT

(W) RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

SPECIFY RIM WIDTH

(S) ANGLE

30° ANGLE

45° ANGLE

24° ANGLE

17° ANGLE

30° ANGLE

(D) DIAMETER:

3.000"

(T) WHEEL HEIGHT:

0.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(S) ANGLE:

30° ANGLE

(D) DIAMETER:

3.000"

(T) WHEEL HEIGHT:

0.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(S) ANGLE:

45° ANGLE

(D) DIAMETER:

4.000"

(T) WHEEL HEIGHT:

0.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(S) ANGLE:

24° ANGLE

(D) DIAMETER:

4.000"

(T) WHEEL HEIGHT:

0.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(S) ANGLE:

17° ANGLE

(D) DIAMETER:

6.000"

(T) WHEEL HEIGHT:

0.500"

(H) ARBOR HOLE:

SPECIFY HOLE SIZE

GRIT SIZE:

SPECIFY GRIT

(W) RIM WIDTH:

SPECIFY RIM WIDTH

(S) ANGLE:

30° ANGLE