12V9 CBN Wheels

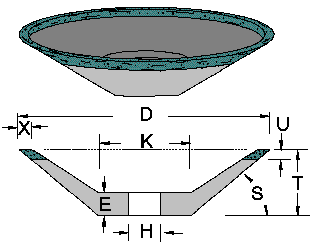

12V9 CBN Wheels Resin Bond are engineered for precision fluting, gashing, and relief grinding of HSS, high-alloy tool steels, cobalt steels, and powdered-metal cutting tools. The 12V9 bowl-shaped geometry provides exceptional edge stability and consistent wheel engagement—ideal for CNC tool grinding and high-accuracy sharpening applications.

Manufactured with premium Cubic Boron Nitride (CBN) and advanced resin bond formulations, these wheels deliver a cool-cutting grind, excellent corner retention, and highly controlled wheel wear. Braemar’s resin systems are optimized to expose sharp CBN particles throughout the wheel’s life, reducing heat, minimizing burning, and maintaining precise tool geometry.

Key Performance Features

Optimized for Hardened Steels & High-Alloy Materials

CBN remains chemically stable with ferrous metals, making 12V9 CBN wheels the ideal choice for:

• HSS (M2, M35, M42)

• Tool steels (A2, D2, S7)

• Powder-metal steels

• Bearing steels (52100)

• High-cobalt and high-chrome alloys

Resin Bond for Cool, Clean Grinding

Braemar’s engineered resin bond provides:

• Cool-cutting action reducing thermal damage

• Controlled bond breakdown for constant sharpness

• Excellent chip flow and low grinding forces

• Superior surface finish and reduced micro-fracturing

Precision Geometry for CNC Tool Grinding

The 12V9 shape provides:

• Stable cutting edge engagement

• Accurate flute & gash form

• Strong corner support for long wheel life

• Consistent wear patterns for predictable performance

Ideal for end mills, step drills, reamers, forming tools, and complex cutting tool geometries.

Applications

- CNC tool grinding (fluting, gashing, relief grinding)

• Sharpening HSS and powdered-metal cutting tools

• Profile and form grinding

• Precision sharpening of step drills, reamers, and taps

• High-accu12V9 CBN Wheels Resin Bond are engineered for precision fluting, gashing, and relief grinding of HSS, high-alloy tool steels, cobalt steels, and powdered-metal cutting tools. The 12V9 bowl-shaped geometry provides exceptional edge stability and consistent wheel engagement—ideal for CNC tool grinding and high-accuracy sharpening applications.Manufactured with premium Cubic Boron Nitride (CBN) and advanced resin bond formulations, these wheels deliver a cool-cutting grind, excellent corner retention, and highly controlled wheel wear. Braemar’s resin systems are optimized to expose sharp CBN particles throughout the wheel’s life, reducing heat, minimizing burning, and maintaining precise tool geometry.

Key Performance Features

Optimized for Hardened Steels & High-Alloy Materials

CBN remains chemically stable with ferrous metals, making 12V9 CBN wheels the ideal choice for:

• HSS (M2, M35, M42)

• Tool steels (A2, D2, S7)

• Powder-metal steels

• Bearing steels (52100)

• High-cobalt and high-chrome alloysResin Bond for Cool, Clean Grinding

Braemar’s engineered resin bond provides:

• Cool-cutting action reducing thermal damage

• Controlled bond breakdown for constant sharpness

• Excellent chip flow and low grinding forces

• Superior surface finish and reduced micro-fracturingPrecision Geometry for CNC Tool Grinding

The 12V9 shape provides:

• Stable cutting edge engagement

• Accurate flute & gash form

• Strong corner support for long wheel life

• Consistent wear patterns for predictable performanceIdeal for end mills, step drills, reamers, forming tools, and complex cutting tool geometries.

Applications

- CNC tool grinding (fluting, gashing, relief grinding)

• Sharpening HSS and powdered-metal cutting tools

• Profile and form grinding

• Precision sharpening of step drills, reamers, and taps

• High-accuracy tool manufacturing & regrind shops

Why Choose Braemar USA?

Braemar USA’s CBN tools are engineered for repeatability, stability, and exceptional grinding efficiency. Every wheel is manufactured to strict tolerances with optimized bond hardness and diamond concentration to match your machine parameters and steel grade.

You can expect:

• Longer wheel life at higher feed rates

• More consistent tool geometry

• Reduced heat, burning, and part distortion

• Superior surface integrity and finish qualityracy tool manufacturing & regrind shops

- CNC tool grinding (fluting, gashing, relief grinding)

Why Choose Braemar USA?

Braemar USA’s CBN tools are engineered for repeatability, stability, and exceptional grinding efficiency. Every wheel is manufactured to strict tolerances with optimized bond hardness and diamond concentration to match your machine parameters and steel grade.

You can expect:

• Longer wheel life at higher feed rates

• More consistent tool geometry

• Reduced heat, burning, and part distortion

• Superior surface integrity and finish quality

Call (480) 966-9311 or Add to Quote for pricing.