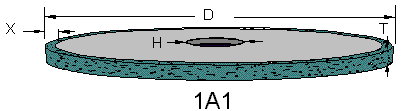

1A1 CBN Wheels

1A1 CBN Wheels Resin Bond– High-Accuracy Grinding for Hardened Steels | Braemar USA

1A1 CBN Wheels are engineered for precision grinding of hardened steels, high-alloy tool steels, and ferrous materials where heat control, surface finish, and edge integrity are critical. The 1A1 flat-profile wheel design delivers exceptional rigidity and stability, making it ideal for surface grinding, cylindrical grinding, OD/ID grinding, and high-accuracy tool manufacturing.

Built using premium synthetic CBN abrasives and advanced resin bond systems, these wheels provide a fast, cool-cutting action that maintains sharp cutting edges throughout the wheel’s life. Braemar USA’s resin matrix is formulated for controlled breakdown—continuously exposing fresh CBN grains for consistent performance, reduced heat, and superior surface quality.

Key Features & Advantages

1. Superior Grinding Performance on Hardened Steels

CBN is the optimal abrasive for ferrous materials because it will not chemically react with iron.

Braemar 1A1 CBN wheels excel in grinding:

-

High-speed steel (HSS)

-

M2, M35, M42 cobalt steels

-

Tool steels (D2, A2, S7, O1)

-

Powder-metal steels

- Spray Materials

-

Bearing steels (52100)

-

Heat-treated alloy steels

-

Nickel-based alloys

2. Cool-Cutting Resin Bond Technology

Braemar’s resin system reduces grinding forces and minimizes thermal damage:

-

Lower heat generation

-

Reduced burning and micro-cracking

-

Improved edge retention

-

Stable, smooth grinding action

3. Excellent Surface Finish & Geometry Retention

The controlled bond structure provides:

-

Fine, consistent surface finishes

-

Reduced wheel loading

-

Minimal chatter

-

Accurate part geometry and dimensional stability

4. Long Wheel Life with Predictable Wear

Our premium resin formulations ensure:

-

High CBN retention

-

Self-sharpening performance

-

Reduced downtime

-

Stable performance in long production runs

Applications

Braemar USA Resin Bond 1A1 CBN Wheels are ideal for:

-

Tool and cutter grinding

-

Surface grinding hardened steels

-

Cylindrical and OD grinding

-

Punches, dies, and high-alloy components

-

Precision toolroom and production applications

-

Automated CNC grinding systems

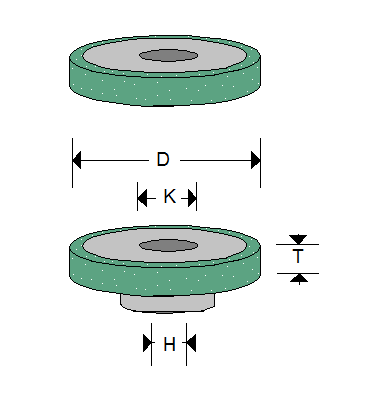

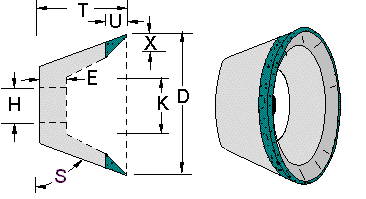

Available Specifications

-

Diameters: 0.500″ to 20.000″+

-

Thicknesses: Wide range from thin-rim to heavy-duty

-

Grit sizes: From coarse to micron finishes

-

Bore sizes: Custom and standard (1.250″, 0.750″, .0625″ 0.500″,0.375″ , etc.)

-

Bond grades: Standard, high-strength, heat-resistant, and premium options

-

Custom formulations available upon request

Why Choose Braemar USA?

Braemar USA provides precision-engineered CBN wheels designed for accuracy, consistency, and maximum value. Our wheels deliver the performance required by tool manufacturers, precision shops, aerospace machining, automotive grinding, and advanced manufacturing environments.

Call (480) 966-9311 or Add to Quote for pricing.