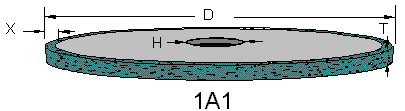

1A1R Diamond Wheels

Braemar USA manufactures 1A1R diamond wheels for precise, stable, and repeatable material removal on demanding materials. The recessed wheel design provides additional clearance for hubs, guards, and adapters. As a result, operators achieve better machine fit, smoother running conditions, and improved balance during operation.

Moreover, each 1A1R diamond wheel maintains a flat and stable cutting face during both light finishing and heavy grinding. This geometry supports clean, consistent surface quality while holding tight dimensional tolerances across long production runs.

Precision Construction for Consistent Results

Braemar USA builds every 1A1R diamond wheel using premium synthetic diamond combined with a carefully controlled bond system. Consequently, users experience predictable wear, long service life, and stable cutting performance. In addition, manufacturers across multiple industries rely on this wheel style when machining hard or brittle materials that demand accuracy and repeatability.

How the Recessed Design Improves Performance

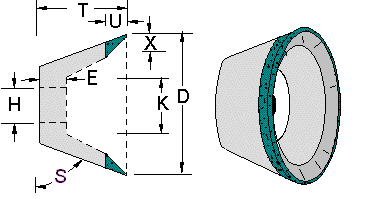

A recessed grinding wheel features a flat working face with a shaped cavity on one or both sides. Because of this design, 1A1R diamond wheels offer several practical advantages:

-

Additional clearance for machine hardware

-

Improved balance at operating speeds

-

Compatibility with a wide range of grinding systems

-

Lower cutting forces supported by rigid wheel geometry

Furthermore, the structure remains stable even during aggressive grinding. Over time, the wheel geometry stays consistent, which enhances accuracy and reduces variation in finished parts.

Bond Options for 1A1R Diamond Wheels

Resin Bond

Resin-bond 1A1R diamond wheels run cool and remain sharp. Since this bond resists glazing, it performs especially well on carbide, ceramics, glass, and sapphire. Additionally, resin bonds help produce smooth surface finishes on precision components.

Metal Bond

Metal-bond wheels deliver excellent form retention and extended tool life. Therefore, they work well for hard technical ceramics, brittle alloys, and high-pressure grinding applications that require consistent wheel shape.

Hybrid Bond

Hybrid bond systems combine fast cutting action with strong shape stability. As a result, they perform exceptionally well on CNC grinders, robotic grinding cells, and continuous-duty production environments.

Performance Advantages

1A1R diamond wheels from Braemar USA offer several performance benefits:

-

Flat faces for accurate dimensions

-

Recessed profiles for improved machine clearance

-

Fast, cool cutting that reduces heat buildup

-

Long wheel life with fewer dressing cycles

-

Even diamond exposure for efficient material removal

-

Smooth finishes on precision tools and components

Together, these advantages deliver reliable accuracy in demanding production environments.

Common Applications

1A1R diamond wheels perform well when grinding:

-

Tungsten carbide tools and inserts

-

Zirconia, alumina, and advanced ceramics

-

Quartz, fused silica, and optical materials

-

Sapphire and silicon carbide

-

Composite materials and PCD tools

-

Hard non-ferrous metals

Because of this versatility, manufacturers use recessed diamond wheels across many high-precision industries.

Compatible Machines

These wheels integrate easily with:

-

CNC grinding centers

-

Tool and cutter grinders

-

Surface grinders

-

Optical and ceramic finishing systems

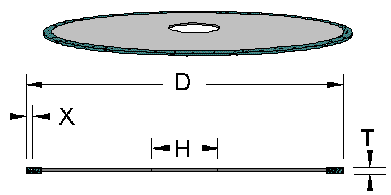

Available Specifications

Braemar USA supplies 1A1R diamond wheels with flexible configurations:

-

Diameters: 1.000″ to 30.000″

-

Recess dimensions: Any depth or diameter

-

Grit options: 20/30 through fine finishing grades

-

Diamond concentration: Low to high

-

Arbor sizes: Custom fit

-

Special geometries: Built to customer print

Why Choose Braemar USA

Braemar USA delivers 1A1R diamond wheels with precise geometry, stable bond structures, and uniform diamond placement. In addition, our technical team helps customers select the ideal grit size, bond type, concentration, and recess dimensions for each application. As a result, every wheel runs true, cuts cleanly, and provides long-lasting, consistent performance.

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

(D) WHEEL DIAMETER

2.000

3.000

4.000

4.000

6.000

6.000

6.000

6.000

7.000

8.000

8.000

10.000

12.000

12.000

14.000

16.000

20.000

(T) WHEEL THICKNESS

0.035

0.035

0.035

0.035

0.032

0.035

0.040

0.060

0.040

0.045

0.060

0.060

0.065

0.065

0.070

0.080

0.080

(H) ARBOR HOLE

0.187

0.750

0.750

20.00mm

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

1.250

5.000

5.000

5.000

5.000

GRIT SIZE

100/120

100/120

100/120

140/170

100/120

100/120

200/220

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

100/120

(D) WHEEL DIAMETER:

2.000

(T) WHEEL THICKNESS:

0.035

(H) ARBOR HOLE:

0.187

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

3.000

(T) WHEEL THICKNESS:

0.035

(H) ARBOR HOLE:

0.750

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

4.000

(T) WHEEL THICKNESS:

0.035

(H) ARBOR HOLE:

0.750

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

4.000

(T) WHEEL THICKNESS:

0.035

(H) ARBOR HOLE:

20.00mm

GRIT SIZE:

140/170

(D) WHEEL DIAMETER:

6.000

(T) WHEEL THICKNESS:

0.032

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

6.000

(T) WHEEL THICKNESS:

0.035

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

6.000

(T) WHEEL THICKNESS:

0.040

(H) ARBOR HOLE:

1.250

GRIT SIZE:

200/220

(D) WHEEL DIAMETER:

6.000

(T) WHEEL THICKNESS:

0.060

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

7.000

(T) WHEEL THICKNESS:

0.040

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

8.000

(T) WHEEL THICKNESS:

0.045

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

8.000

(T) WHEEL THICKNESS:

0.060

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

10.000

(T) WHEEL THICKNESS:

0.060

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

12.000

(T) WHEEL THICKNESS:

0.065

(H) ARBOR HOLE:

1.250

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

12.000

(T) WHEEL THICKNESS:

0.065

(H) ARBOR HOLE:

5.000

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

14.000

(T) WHEEL THICKNESS:

0.070

(H) ARBOR HOLE:

5.000

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

16.000

(T) WHEEL THICKNESS:

0.080

(H) ARBOR HOLE:

5.000

GRIT SIZE:

100/120

(D) WHEEL DIAMETER:

20.000

(T) WHEEL THICKNESS:

0.080

(H) ARBOR HOLE:

5.000

GRIT SIZE:

100/120