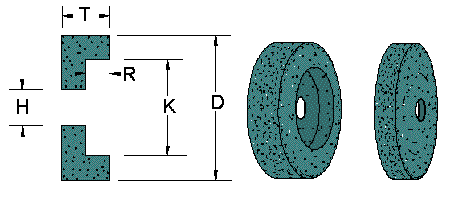

1A8S CBN Wheels

1A8S specialized super abrasive wheels designed for internal diameter (ID) grinding of hard ferrous materials. 1A8S solid CBN wheels are composed almost entirely of CBN abrasive material—meaning the cutting section isn’t just a thin abrasive layer but a continuous CBN structure (or a very thick bond/abrasive ratio).These wheels come in standard diameters ranging from 0.375″ to 3.000.

Key Features:

- Construction: Solid abrasive layer of CBN (often in a vitrified or resin), rather than an electroplated or thin-coated design.

- Durability: Extremely long tool life due to the high concentration of CBN throughout the wheel.

- Precision: Maintains tight tolerances in bore sizing, roundness, and surface finish.

- Thermal Stability: CBN withstands high temperatures without rapid wear—ideal for hardened steels and alloys.

- Form Holding: Solid design resists shape loss during extended grinding cycles.

Applications:

- Internal grinding of bearing races, fuel injection components, hydraulic parts, gears, and precision bushings.

- Machining of hardened steels, tool steels, superalloys, and other ferrous materials where conventional abrasives (aluminum oxide, silicon carbide) fail.

- Situations requiring very fine surface finishes (Ra < 0.2 µm) and high geometrical accuracy.

Call (480) 966-9311 or Add to Quote for pricing.