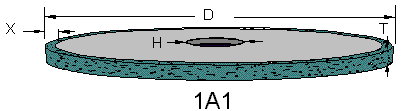

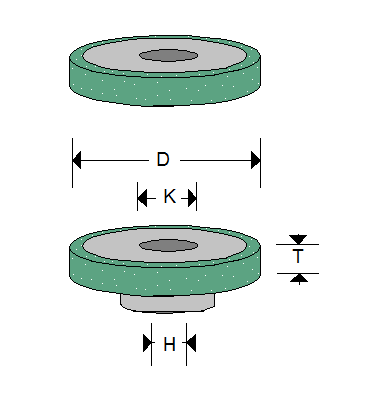

1A8SP CBN Wheels

1A8SP CBN Wheels-Resin Bond from Braemar USA are engineered for precision grinding of hardened steels, high-alloy tool steels, and ferrous materials where slotting, profiling, and narrow-rim grinding performance is critical. The 1A8SP shape features a specialized rim profile with enhanced rigidity, allowing the wheel to maintain geometry under heavy grinding pressures and extended production cycles.

Designed using premium CBN abrasive and a high-performance resin bond matrix, these wheels deliver a cool-cutting action, reduced heat generation, and exceptional edge stability. The resin bond provides controlled breakdown, continuously exposing fresh, sharp CBN crystals—ideal for operations where consistent surface finish and repeatable dimensional accuracy are required.

1A8SP Wheel Features

-

Thin, reinforced rim profile for narrow-slot and form-grinding

-

High-strength resin bond with optimized grit retention

-

Self-sharpening action for stable cutting performance

-

Reduced thermal damage and minimized burning

-

Excellent wheel life in high-precision ferrous-metal grinding

Engineered for Hardened Steels

Use 1A8SP CBN resin wheels for:

-

M2, M35, M42 high-speed steels

-

D2, A2, S7 tool steels

-

Bearing steels (52100)

-

Powder-metal and alloy steels

-

High-alloy ferrous components

Industries & Applications

-

Tool & cutter manufacturing

-

Punch & die production

-

Precision slot grinding

-

Profile and form grinding

-

Automotive & aerospace component machining

-

High-accuracy fixture and gauge production

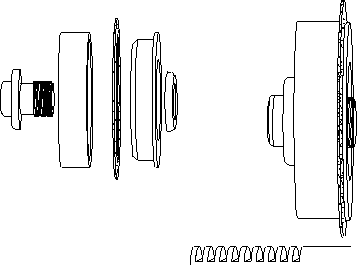

Braemar USA’s 1A8SP CBN Resin Bond wheels are built for manufacturers who require tight tolerances, clean grinding action, and long-life performance in demanding production environments.

Call (480) 966-9311 or Add to Quote for pricing.