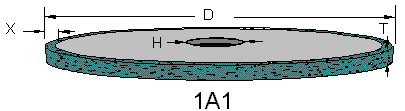

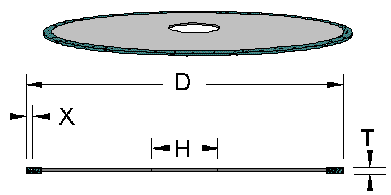

1A8SP Precision Resin Bond Diamond Slotting Wheel

1A8SP Precision Resin Bond Diamond Slotting Wheels are engineered for precision slotting, notch grinding, and fine-detail shaping of carbide, ceramics, glass, sapphire, quartz, and other advanced materials. The 1A8SP profile features a specialized thin-rim design that allows operators to grind narrow features, produce micro-grooves, and finish intricate contours with exceptional accuracy.

Built using Braemar’s high-performance resin bond system, these wheels deliver:

-

Cool-cutting action with reduced grinding heat

-

Controlled breakdown for consistent diamond exposure

-

Sharp cutting edges that maintain form accuracy

-

Excellent surface finish on brittle and hard materials

The 1A8SP shape is widely used in tool grinding, optical component manufacturing, semiconductor machining, and micro-precision engineering, where ultra-tight tolerances and clean edge integrity are essential.

Braemar’s resin bond formulations offer long wheel life, high chip-resistance, and predictable wear—critical for CNC tool grinders, profile grinders, and specialized precision grinding setups. Custom grit sizes, concentrations, and rim widths are available to match your application.

Choose Braemar USA 1A8SP Diamond Wheels for reliable performance in demanding production environments requiring thin-profile accuracy, smooth finishes, and stable grinding behavior.

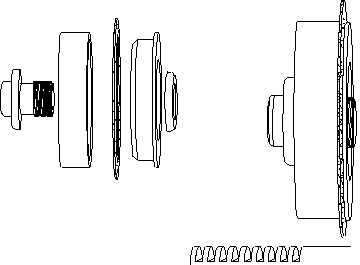

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.