1V1 CBN Wheels

1V1 CBN Wheels – Resin Bond – Braemar USA

High-Precision Fluting, Gashing & Edge Grinding for Hardened Steels

Braemar USA 1V1 CBN Wheels are engineered for high-accuracy grinding applications that demand sharp cutting ability, precise form retention, and exceptional thermal control when working with hardened steels and high-alloy materials. The 1V1 shape features a sharp, tapered profile ideal for gashing, clearance grinding, tool sharpening, relief work, and CNC tool manufacture.

Built with a premium resin bond matrix, these wheels deliver a cool-cutting grind with low heat generation—critical for preventing burning, micro-cracking, and edge deformation in HSS, high-cobalt steels, and powdered-metal tool steels.

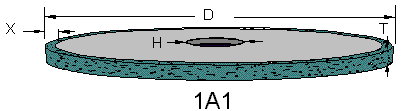

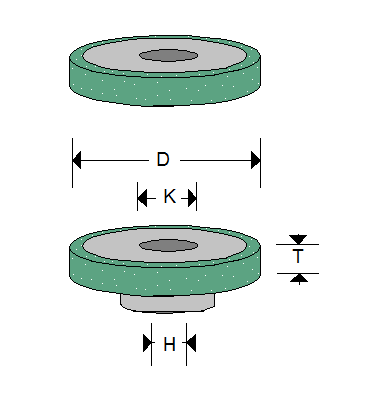

1V1 CBN Wheel Shape – Precision Tapered Profile

The 1V1 form provides:

-

A sharp, tapered diamond/CBN rim for precision edge work

-

Ideal geometry for fluting, gashing, and tool-relief grinding

-

Stable profile retention for tight-tolerance CNC tool grinding

-

Excellent access for small-diameter features and complex geometry

This design allows exceptional control when grinding drills, step tools, cutters, end mills, re-sharpening tools, and complex cutting edges.

Resin Bond Advantages

Braemar’s high-strength resin bond technology provides:

-

Cool-cutting performance to reduce burning and maintain edge integrity

-

Controlled breakdown for constant exposure of sharp CBN particles

-

Fine surface finish on HSS and high-alloy steels

-

Reduced grinding forces, improving tool life and accuracy

-

Longer wheel life in demanding tool-room and CNC applications

Resin bond is the preferred choice for tool-manufacturing environments where heat management, accuracy, and finish quality are essential.

Optimized for Hardened Steels & High-Alloy Materials

Braemar USA 1V1 CBN Wheels perform exceptionally on:

-

High-speed steel (HSS)

-

M2, M35, M42 cobalt steels

-

D2, A2, S7 tool steels

-

Powder-metal steels

-

Bearing steels (52100)

-

Nickel-based and high-alloy materials

The CBN abrasive maintains sharpness and stability while providing consistent grinding results over long production runs.

Applications

-

CNC tool grinding

-

Fluting and gashing

-

Drill and end-mill sharpening

-

Clearance and relief angle grinding

-

Precision cutting tool manufacturing

-

Regrinding and edge preparation

-

Small-diameter or detail grinding

Why Choose Braemar USA?

Braemar USA combines advanced resin bond engineering, premium CBN abrasive, and strict geometric tolerances to deliver wheels that offer:

-

Improved cutting efficiency

-

Predictable wear for consistent performance

-

High accuracy for modern CNC grinding equipment

-

Exceptional surface finish quality

-

Extended wheel life

When precision, repeatability, and tool-edge quality matter, Braemar USA resin bond 1V1 CBN wheels deliver industry-leading performance.

Call (480) 966-9311 or Add to Quote for pricing.