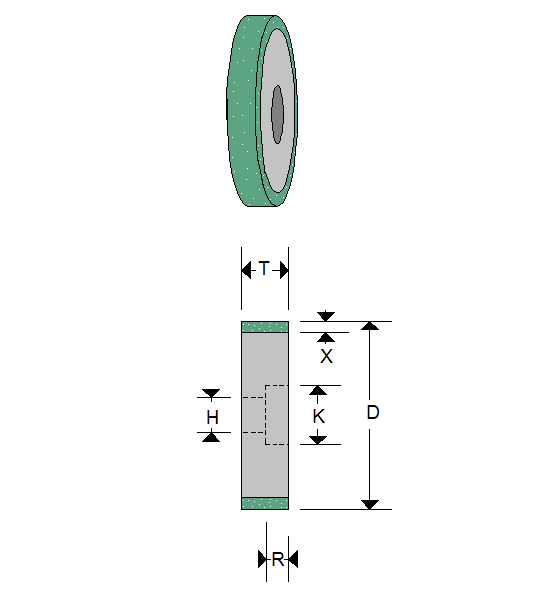

3A1 / 1A1-CB CBN Wheels

3A1 / 1A1-CB CBN Wheels Resin Bond– High-Precision Grinding for Hardened Steels | Braemar USA

3A1 / 1A1-CB CBN Resin Bond Wheels are engineered for high-accuracy grinding of hardened steels, high-alloy tool steels, bearing steels, and HSS materials. Built using premium cubic boron nitride, a controlled resin bonding system, and precise wheel geometry, these wheels deliver fast cutting, cooler grinding, and superior surface integrity in demanding production environments.

Ideal for CNC tool grinding, surface grinding, OD/ID grinding, and fine-finish applications, Braemar’s resin bond CBN wheels provide a consistent, predictable grinding action that enhances tool accuracy, reduces thermal damage, and extends wheel life.

High-Performance Resin Bond System

The advanced Braemar resin bond matrix ensures:

-

Cool-cutting performance with low grinding forces

-

Self-sharpening behavior through controlled bond breakdown

-

Stable geometry retention for tight-tolerance operations

-

Reduced burn, thermal cracks, and distortion on hardened steels

The bond exposes new, sharp CBN grains as the wheel wears, maintaining aggressive cutting without sacrificing surface quality.

3A1 & 1A1-CB CBN Wheel Advantages

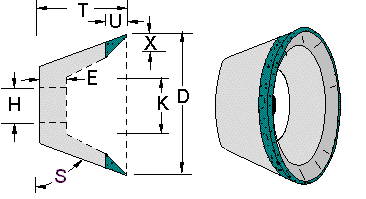

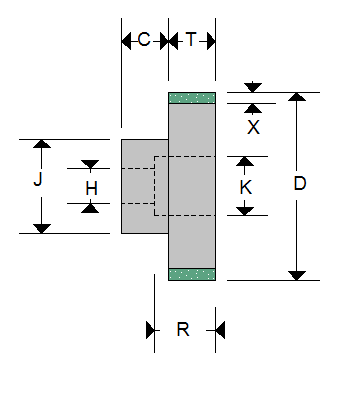

3A1 – Precision Flared Cup CBN Wheel

-

Excellent for tool grinding and detail geometry work

-

Superior edge accessibility

-

Stable rim structure for high-accuracy grinding

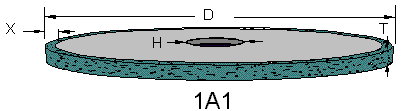

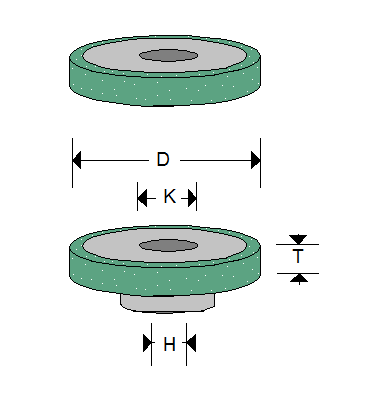

1A1-CB – Straight Wheel with Continuous Rim

-

Wide contact surface for stable, uniform grinding

-

Ideal for cylindrical, surface, and OD/ID grinding

-

High stock-removal capability with fine finish options

Engineered for Hardened Steel Applications

Braemar resin bond CBN wheels excel when grinding:

-

High-Speed Steel (HSS)

-

M2, M35, M42 cobalt steels

-

A2, D2, S7 cold & hot-work tool steels

-

52100 bearing steel

-

Powder-metal steels

-

Die steels & high-alloy metals

-

Nickel-based alloys

Because CBN does not react with iron, it is the correct abrasive for all ferrous tool-steel grinding applications.

Consistent Precision for Advanced Grinding Systems

Designed for:

-

CNC tool grinders

-

Surface grinders

-

Cylindrical / OD / ID grinders

-

Tool-room grinding

-

Automated high-volume production

Braemar’s manufacturing precision ensures balanced wheels, accurate arbor fitment, and uniform diamond/CBN distribution for long, trouble-free performance.

Custom Specifications Available

Braemar USA provides full customization:

-

Grit sizes from coarse to micron finish

-

Variable bond hardness

-

Special rim widths & modified 3A1 flares

-

Coolant-optimized structures

-

High-precision tolerances

-

Custom hubs & mountings

Why Choose Braemar USA?

Braemar USA delivers production-grade CBN wheels engineered for accuracy, heat control, wheel life, and repeatability. Each wheel is built to maintain geometry under demanding loads while producing clean, consistent finishes in hardened-steel grinding operations.

Call (480) 966-9311 or Add to Quote for pricing.