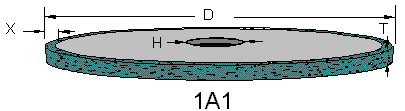

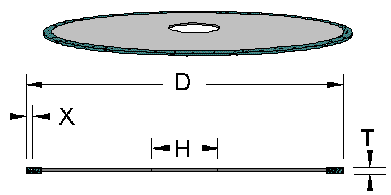

3A1 / 1A1-CB Diamond Wheels

3A1/1A1-CB Diamond Wheels for ID grinding hard materials are engineered for precision internal grinding applications where superior surface finish and tight dimensional control are required. Designed with a resin bond matrix, this wheel offers excellent grinding efficiency, reduced heat generation, and minimal work piece damage.

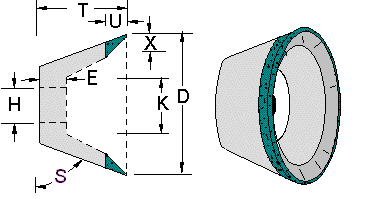

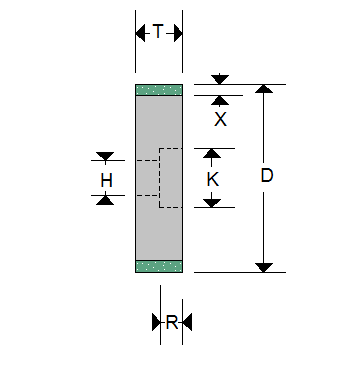

Ideal for internal grinding carbide, ceramics, glass, silicon carbide, and many other advanced materials. Resin bond 3A1 wheels provides a free-cutting action with superior self-sharpening properties, extending wheel life while maintaining consistent performance. The 3A1 configuration has a counter/bore for proper mounting and ensures optimal balance and stability for high-speed internal diameter (ID) grinding machines.

Key Features:

- High-precision 3A1 design for internal diameter grinding

- Resin bond ensures cool cutting and excellent surface finish

- Suitable for hard and brittle materials such as tungsten carbide, ceramics, and glass

- Long tool life with consistent form retention

- Available in various grit sizes and concentrations to match specific application needs

Applications:

- Internal grinding of precision components

- Finishing of carbide dies, bearings, and ceramic sleeves

- Tool and cutter manufacturing and regrinding

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

STYLE

1A1-CB

1A1-CB

1A1-CB

1A1-CB

1A1-CB

3A1

3A1

1A1-CB

3A1

1A1-CB

3A1

D

0.625

0.750

0.750

1.000

1.235

1.500

2.000

3.000

3.000

4.000

4.000

T

0.375

0.500

0.500

0.500

1.000

0.500

0.500

0.500

0.500

0.500

0.500

H

0.250

0.250

0.375

0.375

0.375

0.375

0.375

0.375

0.375

0.375

0.375

K

0.400

0.400

0.400

0.500

0.750

0.625

0.750

1.000

1.500

1.500

1.500

R

0.187

0.250

0.250

0.250

0.500

0.500

0.500

0.250

0.500

0.250

0.500

J

N/A

N/A

N/A

N/A

N/A

0.750

1.000

N/A

2.000

N/A

3.000

C

N/A

N/A

N/A

N/A

N/A

0.500

0.500

N/A

0.500

N/A

0.500

GRIT

060/800

060/800

060/800

060/800

060/800

060/800

060/800

060/800

060/800

060/800

060/800

STYLE:

1A1-CB

D:

0.625

T:

0.375

H:

0.250

K:

0.400

R:

0.187

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

1A1-CB

D:

0.750

T:

0.500

H:

0.250

K:

0.400

R:

0.250

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

1A1-CB

D:

0.750

T:

0.500

H:

0.375

K:

0.400

R:

0.250

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

1A1-CB

D:

1.000

T:

0.500

H:

0.375

K:

0.500

R:

0.250

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

1A1-CB

D:

1.235

T:

1.000

H:

0.375

K:

0.750

R:

0.500

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

3A1

D:

1.500

T:

0.500

H:

0.375

K:

0.625

R:

0.500

J:

0.750

C:

0.500

GRIT:

060/800

STYLE:

3A1

D:

2.000

T:

0.500

H:

0.375

K:

0.750

R:

0.500

J:

1.000

C:

0.500

GRIT:

060/800

STYLE:

1A1-CB

D:

3.000

T:

0.500

H:

0.375

K:

1.000

R:

0.250

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

3A1

D:

3.000

T:

0.500

H:

0.375

K:

1.500

R:

0.500

J:

2.000

C:

0.500

GRIT:

060/800

STYLE:

1A1-CB

D:

4.000

T:

0.500

H:

0.375

K:

1.500

R:

0.250

J:

N/A

C:

N/A

GRIT:

060/800

STYLE:

3A1

D:

4.000

T:

0.500

H:

0.375

K:

1.500

R:

0.500

J:

3.000

C:

0.500

GRIT:

060/800