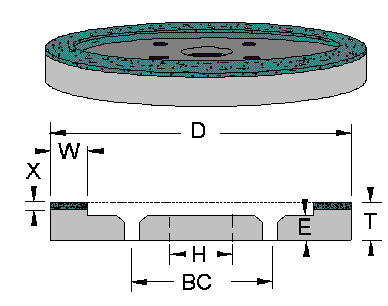

6A2C CBN Wheels

6A2C CBN Wheels are engineered for high-precision grinding of hardened steels, high-alloy metals, and ferrous materials where heat control, edge integrity, and form accuracy are critical. The 6A2C hybrid cup/face profile offers exceptional rigidity, clean cutting, and precise corner definition—making it ideal for tool grinding, surface grinding, clearance grinding, and OD/ID applications requiring consistent geometry and a superior surface finish.

Manufactured using premium CBN abrasive and advanced resin bond technology, Braemar’s 6A2C wheels deliver a fast, cool-cutting grind with minimal thermal damage, making them the preferred choice for tool rooms, CNC grinding systems, and high-accuracy production environments.

Key Features

Precision 6A2C Shape

-

Hybrid dish/cup profile with reinforced sidewalls

-

Excellent corner strength for detailed tool geometry

-

Stable form under heavy or intermittent grinding loads

Advanced Resin Bond Construction

-

Cool-cutting, free-cutting bond system

-

Controlled breakdown exposes fresh CBN for consistent cutting

-

Reduced burning, micro-cracking, and thermal distortion

-

Ideal for fine finishes and aggressive stock removal

Engineered for Ferrous Materials

Perfect for grinding:

-

Hardened steels (A2, D2, S7)

-

High-speed steel (HSS, M2, M42)

-

Tool steels & die steels

-

Powder-metal steels

-

Bearing steels (52100)

-

Nickel-based alloys

Applications

Braemar 6A2C CBN wheels are widely used in:

-

Tool & cutter grinding

-

Surface and profile grinding

-

CNC clearance grinding

-

Insert & cutter fabrication

-

End mill & drill flute grinding

-

Precision OD/ID steel grinding

Why Choose Braemar USA?

Braemar USA designs resin bond CBN wheels for superior performance, stability, and grinding accuracy. Our bond systems are engineered for:

-

Extended wheel life

-

Minimal wheel loading and glazing

-

Sharp, consistent cutting action

-

Precision form retention in demanding environments

Built for carbide tool manufacturers, aerospace machining, automotive toolrooms, mold shops, and high-performance steel grinding operations.

Call (480) 966-9311 or Add to Quote for pricing.