9A3 CBN Wheels

9A3 CBN Wheels Resin Bond are engineered for high-precision grinding of hardened steels, high-alloy tool steels, powder-metal materials, and ferrous components where edge accuracy and cool-cutting performance are essential. The 9A3 wheel shape features a flaring cup profile that provides excellent stability, rigidity, and visibility into the grinding zone—ideal for tool room operations, CNC tool grinding, and precision form grinding.

Manufactured with premium cubic boron nitride (CBN) and advanced resin-bond systems, these wheels provide controlled breakdown, consistent sharpness, and exceptional thermal stability. Braemar USA formulates each 9A3 wheel for reduced grinding forces, minimal heat generation, and superior surface finishes in demanding production environments.

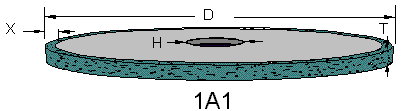

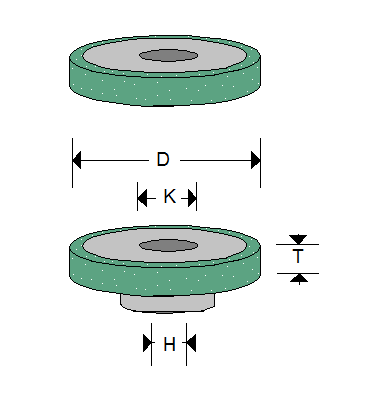

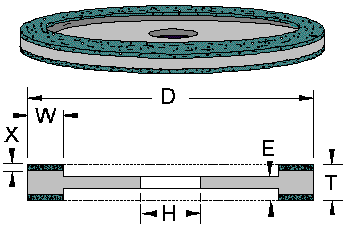

9A3 CBN Wheel Shape

-

Flaring cup profile with a controlled angle for stability

-

Ideal for sharpening, relief grinding, and surface/form applications

-

Excellent operator visibility and coolant access

-

Maintains geometry for mid-profile and fine-form grinding

Resin Bond Advantages

-

Cool-cutting performance—resin absorbs grinding forces and reduces heat

-

Self-sharpening behavior ensures continuous exposure of fresh CBN

-

Superior surface finish on hardened steels and tool steels

-

Less risk of burning, thermal cracking, or workpiece deformation

-

Available in standard, heat-resistant, and Braemar Super Bond resin systems

Material Compatibility

Use Braemar 9A3 CBN wheels for grinding:

-

High-speed steel (HSS)

-

M2, M35, M42 cobalt steels

-

D2, A2, S7, and other tool steels

-

Die steels and bearing steels

-

PM steels

-

Alloy steels and ferrous components

Applications

Perfect for:

-

End mill and cutter sharpening

-

Drill and reamer grinding

-

Tool room grinding

-

CNC tool grinding centers

-

Surface grinding and edge grinding

-

Precision finishing of hardened steel parts

Why Choose Braemar USA 9A3 CBN Wheels?

-

Consistent form accuracy and long wheel life

-

Controlled diamond/CBN exposure for predictable grinding performance

-

Custom grits, concentrations, bond hardness, and cup angles available

-

Engineered for both manual and automated grinding equipment

Call (480) 966-9311 or Add to Quote for pricing.