Brake Dresser

Careful wheel mounting is essential when grinding with a Diamond or CBN wheel. For best performance, the wheel should be mounted perfectly normal and concentric to the machine spindle. Out of roundness is not a major problem with cup and face wheels. Straight diamond wheels such As Type 1A1 usually require truing after mounting. An out of round straight wheel will pound the work piece surface, reducing wheel life and impairing surface finish. This can be avoided by truing the wheel so its entire surface is concentric with the spindle within 0.0005 inch (.0127mm.) Resin-bonded and metal bonded wheels can be trued, using A silicon carbide brake controlled truing device.

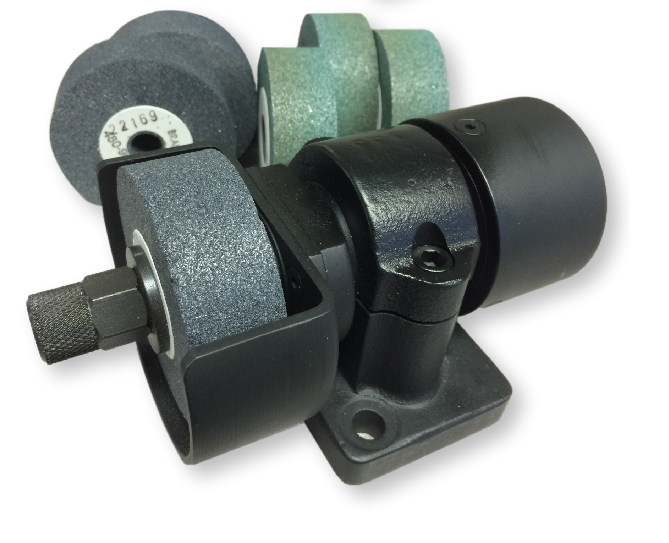

Braemar Brake Control Truing Device Instructions

This tool has been developed for truing various types of Metal bond, Resin Bond and Vitrified Diamond and CBN wheels

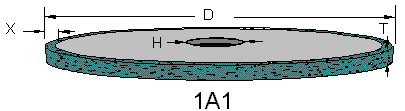

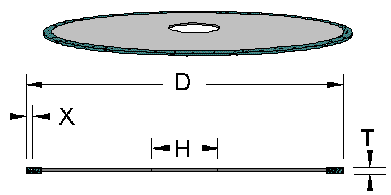

1 1A1 (Straight Wheels)

2 1A1R (Cut off wheels)

3 Mounted and un-mounted internal grinding wheels

4 1V1 Angle Wheels

5 11V9 Cup Wheels

6 Core drill outer diameters

Truing Procedure

After the truing tool is been properly set up bring the Diamond or CBN wheel in the truing wheel together to just avoid making contact. Run the Diamond or CBN wheel at operating speed then start the truing wheel spinning in the direction of rotation of the Diamond or CBN wheel at point of contact, in other words in the same direction it will rotate when driven by the Diamond or CBN wheel

Instructions

The truing device should be mounted so that its wheel spindle is parallel to that of a Peripheral type wheel or perpendicular to that of a cylinder or cup type wheel. At the end of each pass the truing wheel should run off the Diamond or CBN wheel otherwise it may chip at the edges. Use either hand or machine cross feed. Internal grinders a rotary table type surface greatest require that the table on which the tool is clamp remain stationary during the truing operation.

Truing wheel speed

For average truing operations the most effective truing wheel speed is between 1000 and 1500 surface feet per minute. Excessive wear of the dressing wheel will result if too low of a speed is employed. Too high of a speed will result in the lack of truing wheel wear which is essential for effective truing.

While the truing wheel is still spinning bring the two wheels together until they make contact. Pass one wheel back-and-forth across the face of the other at a rate of 30 to 60 inches per minute, with the down feed of .0005” to .001” at the end of each stroke. Completion of the trimming operation is indicated by even continuous contact of wheels.

Cross feeding it reads faster than 60 inches per minute or with down feeds and excessive .001” per pass may result in a slightly crown face on the Diamond or CBN wheel. On the final pass reduced the down feed 2.0005 per pass. Resin bond diamond and CBN wheels offer less resistance to truing the metal or vitrified bonded wheels and should be checked for truth with an indicator after .005” to .010” total truing fee to avoid unnecessary loss of Diamond and CBN wheel.

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.