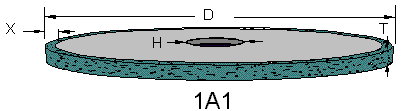

1A1R CBN Cut off Wheels

1A1R CBN Cut-Off Wheels Resin Bond – Precision Cutting for Hardened Steels | Braemar USA

1A1R CBN Cut-Off Wheels Resin Bond are engineered for fast, cool, and burr-free cutting of hardened steels, high-alloy metals, tool steels, and ferrous materials. Built with premium CBN abrasive and a controlled-breakdown resin matrix, these wheels deliver clean, precise cuts with minimal heat generation—ideal for applications where edge integrity, part accuracy, and metallurgical stability cannot be compromised.

Designed for tool rooms, precision manufacturing, and production environments, 1A1R CBN cut-off wheels provide exceptional performance on high-hardness materials that would quickly wear out conventional abrasive wheels.

Why Choose Braemar USA 1A1R Resin Bond CBN Cut-Off Wheels?

1. Superior Cutting Performance on Hardened Steels

CBN is the optimal abrasive for ferrous metals, resisting heat and chemical breakdown during high-speed cutting. Perfect for:

-

High-speed steel (HSS)

-

D2, A2, M2, M35, M42 tool steels

-

Bearing steels (52100)

-

Powder-metal steels

-

Heat-treated and through-hardened parts

-

Die steels, alloy steels, and hardened shafts

The 1A1R design ensures a rigid, stable cutting path with controlled wheel wear.

2. Resin Bond for Cool, Controlled Cutting

Braemar’s resin bond system offers:

-

Low grinding forces

-

Reduced heat generation

-

Minimal burning or temper loss

-

Clean surfaces with reduced burr formation

The bond self-sharpens during cutting, constantly exposing fresh CBN grains for consistent performance.

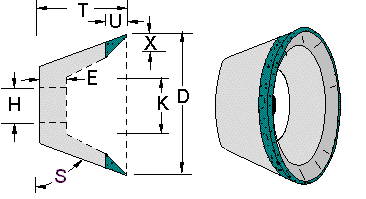

3. Precision Geometry & Long Wheel Life

The 1A1R shape provides:

-

A reinforced side wall for stability

-

Thin kerf capability for fine, accurate cuts

-

Excellent dimensional control

-

Longer life than conventional resin-bonded abrasives

Ideal for cutting small components, carbide-tipped tools, hardened metal rods, inserts, and precision tooling.

4. Built for Production, Tool Rooms, & QC Labs

Common applications include:

-

Cut-off operations for metallurgical testing

-

Cutting hardened shafts and tool blanks

-

Trimming heat-treated components

-

Sectioning parts for inspection

-

High-accuracy cutoff in CNC tool manufacturing

Braemar USA wheels maintain performance across manual, semi-automatic, and automated processes.

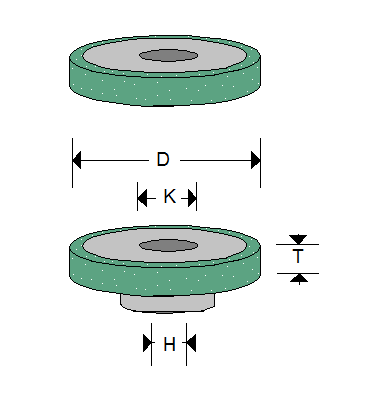

Available Specifications

Customizable 1A1R CBN cut-off wheels available with:

-

Thicknesses from ultra-thin to reinforced heavy-duty

-

CBN grit size (coarse to micron)

-

Standard and premium resin bond systems

-

Arbor sizes and custom hubs

-

Reinforced or non-reinforced constructions

Every wheel is engineered for stability, straight cutting, and long life in high-stress operating environments.

Optimize Your Cutting Performance With Braemar USA

Braemar USA delivers accurate, long-life resin bond CBN wheels for customers who demand consistent, high-precision cut-off results. Each wheel is manufactured to tight tolerances using high-quality CBN, optimized resin systems, and precise geometry control.

Call (480) 966-9311 or Add to Quote for pricing.