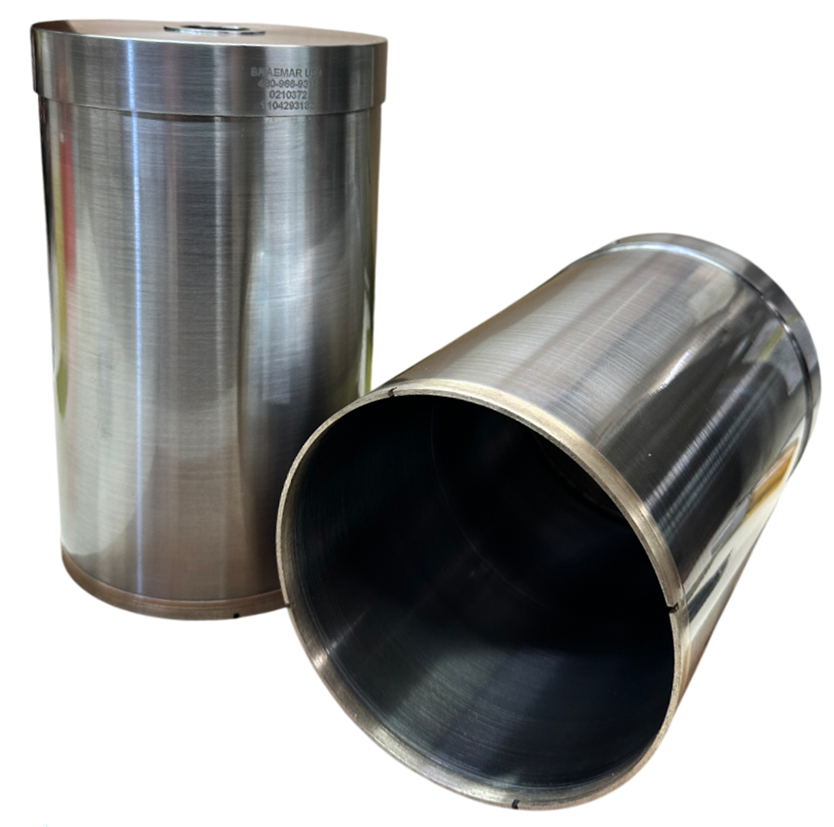

Diamond Core Drill Facts

Drilling small holes (under 1/8″ or 3.18 mm) used to require specialized machines. Today, CNC milling centers have made it much easier. These machines can drill holes as small as 0.025″ with coolant delivered through the center of the drill.

Manual Machines:

-

Use the pecking method — lifting and lowering the drill repeatedly — to keep coolant at the cutting edge.

-

This method helps prevent overheating and extends tool life.

CNC Machines:

-

Allow for continuous drilling through the workpiece.

-

Faster operation with longer tool life.

-

Note: This applies only to core drills. Solid drills still require the pecking method.

Recommended Equipment

To consistently drill clean, chip-free holes, the entire setup must be solid and precise:

-

Use a high-quality, vibration-free machine.

-

The machine must allow proper speeds and sensitive feed control.

-

Mount it on a sturdy base and regularly check spindle run-out.

-

Make sure the workpiece is firmly clamped.

-

Spindle bearings must be in good condition for smooth and accurate drilling.

Choosing the Right Diamond Grit

Diamond grit size affects both performance and finish. Grits range from coarse (20/30) to fine (270/320).

-

Coarse grits (20/30):

-

Faster material removal

-

Rougher finish

-

Best for high-speed or bulk removal where finish isn’t critical

-

-

Fine grits (150 to 320):

-

Slower but cleaner cuts

-

Better suited for delicate materials or precision work

-

Tip: Always match the grit size to the drill size and the material you’re drilling.

Coolant is Critical

Never drill dry with diamond core drills. Coolant is essential for two key reasons:

-

Keeps the drill and material cool

-

Flushes out debris that can clog the drill and cause damage

Coolant Best Practices:

-

Use a coolant additive to improve flow and flushing.

-

Ideal setup: Coolant fed through the center of the drill under controlled pressure.

-

For solid drills, a high-volume flow directed externally is fine.

Recommended Coolant Pressures:

-

0.027″ drill: ~120 psi

-

1.0″ drill: ~50–60 psi

For production work, a CNC milling center with through-spindle coolant is ideal.

Call (480) 966-9311 or Add to Quote for pricing.