Diamond Lapping Compound

Diamond lapping compound is a high-performance abrasive solution designed for precision lapping, polishing, and surface finishing of extremely hard materials. Because it uses micron-graded synthetic diamond particles, it delivers consistent cutting action, excellent surface control, and repeatable results.

This compound is commonly used on carbide, ceramics, sapphire, glass, quartz, silicon carbide, and other advanced materials. In addition, it provides fast material removal while maintaining tight tolerances and superior surface finishes.

Diamond lapping compound is available in a wide range of grit sizes, allowing users to move smoothly from aggressive stock removal to fine polishing. Furthermore, it can be supplied in oil-based or water-based carriers to match different processes, machines, and cleanup requirements.

As a result, this compound is ideal for tool rooms, optical labs, research facilities, and production environments. Overall, diamond lapping compound offers reliable performance, long abrasive life, and precise surface finishes for demanding lapping and polishing applications.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

ITEM#

DLC1801

DLC1803

DLC1806

DLC1809

DLC1812

DLC1815

DLC1820

DLC1830

DLC1845

DLC1860

MICRON SIZE

1

3

6

9

12

15

20

30

45

60

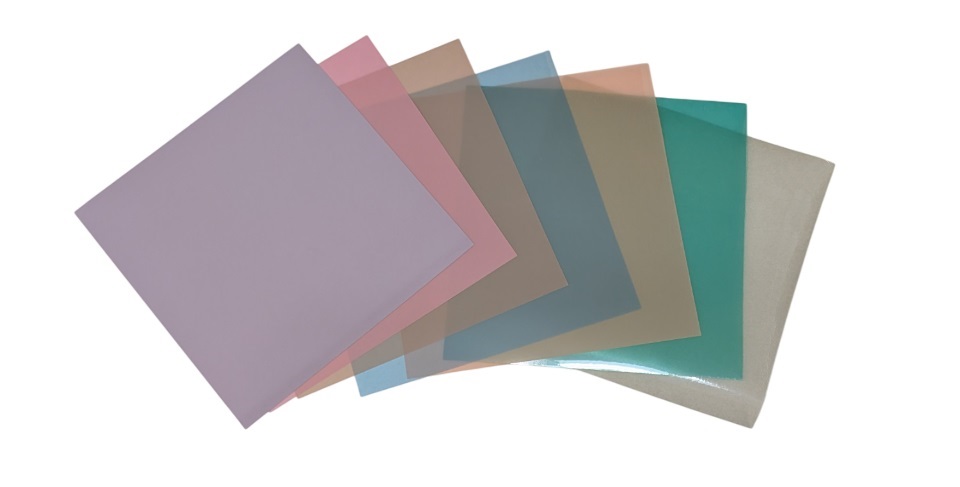

COLOR

IVORY

YELLOW

ORANGE

GREEN

AQUA

BLUE

AUBURN

RED

BROWN

PURPLE

GRAMS

18

18

18

18

18

18

18

18

18

18

ITEM#:

DLC1801

MICRON SIZE:

1

COLOR:

IVORY

GRAMS:

18

ITEM#:

DLC1803

MICRON SIZE:

3

COLOR:

YELLOW

GRAMS:

18

ITEM#:

DLC1806

MICRON SIZE:

6

COLOR:

ORANGE

GRAMS:

18

ITEM#:

DLC1809

MICRON SIZE:

9

COLOR:

GREEN

GRAMS:

18

ITEM#:

DLC1812

MICRON SIZE:

12

COLOR:

AQUA

GRAMS:

18

ITEM#:

DLC1815

MICRON SIZE:

15

COLOR:

BLUE

GRAMS:

18

ITEM#:

DLC1820

MICRON SIZE:

20

COLOR:

AUBURN

GRAMS:

18

ITEM#:

DLC1830

MICRON SIZE:

30

COLOR:

RED

GRAMS:

18

ITEM#:

DLC1845

MICRON SIZE:

45

COLOR:

BROWN

GRAMS:

18

ITEM#:

DLC1860

MICRON SIZE:

60

COLOR:

PURPLE

GRAMS:

18