Diamond Lapping Film

Diamond Lapping Film for Ultra Finishing. Clean Results. Superior Efficiency.

Braemar USA’s Diamond Lapping Film offers a precise, cleaner alternative to traditional diamond slurries and compounds. Engineered for high-performance polishing, this film not only reduces processing time but also enhances surface flatness. Additionally, it eliminates the mess and waste typically associated with slurry-based systems. As a result, it provides exceptional results for industries that require superior surface finishes and tight tolerances.

Key Features:

-

Uniform Diamond Distribution:

To begin with, our Diamond Lapping Film is designed with a uniform distribution of synthetic diamond particles. This ensures fast, consistent material removal, delivering superior finish quality every time. Furthermore, it reduces the number of polishing steps required, making it perfect for achieving high-precision finishes on tough, brittle materials such as ceramics, glass, and carbide. -

Durable 5 Mil Polyester Backing:

Moreover, the 5 mil polyester backing is highly durable and strikes the ideal balance between flexibility and rigidity. As a result, it allows precise handling and consistent performance even under high-pressure applications. In addition, the backing is resistant to tearing and stretching, providing reliable results with every use. -

Versatile Applications:

In addition to its durability, the Diamond Lapping Film excels in a wide range of applications, including:-

Superfinishing Thermal Spray Coatings: Perfect for polishing and finishing coated surfaces, ensuring a smooth, uniform layer.

-

Polishing Ceramics & Carbides: Achieve exceptional flatness and finish quality on materials used in technical ceramics, carbide tooling, and wear-resistant parts.

-

Chilled Iron & Granite: Ideal for polishing hard, dense materials, offering fine, precise finishes.

-

Glass & Optical Materials: Our film is reliable for applications requiring high-precision finishes on glass and optical components, where tight tolerances are critical.

-

-

Clean Process:

One of the standout features of this product is the elimination of slurry cleanup and disposal. As a result, there is no need for messy liquid coolants or abrasive slurries, making the film a cleaner and more eco-friendly solution. This not only reduces material waste but also minimizes the environmental impact. In turn, it leads to a safer and healthier working environment with less downtime.

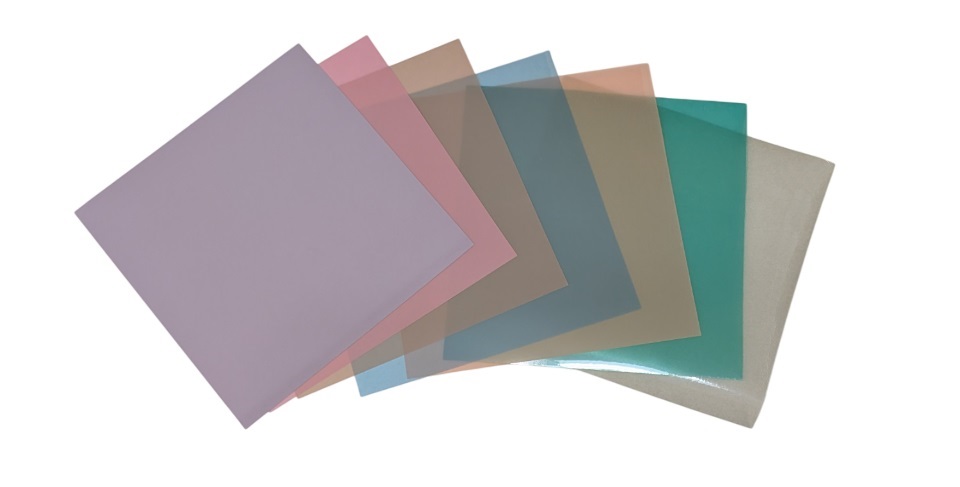

Available Grades:

Braemar USA’s Diamond Lapping Film is available in a variety of grades to meet your specific finishing requirements:

-

1, 3, 6, 9, 20, 30, 45, 74, and 125 micron grades, enabling you to choose the perfect abrasive size based on your application. Whether you need fine polishing or aggressive material removal, we have the right solution for you.

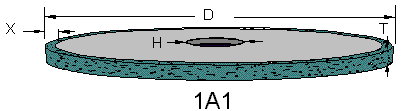

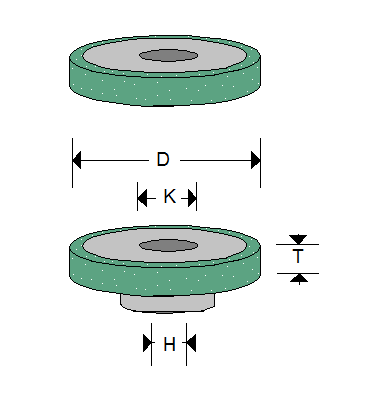

Formats Available:

We offer multiple formats to suit your workflow and equipment needs:

-

Rolls: Ideal for large-scale production environments, providing continuous use and customizable lengths.

-

Belts: Perfect for automated machines, delivering long-lasting performance in high-volume operations.

-

Discs: Convenient for manual polishing applications or use with orbital sanders.

-

Sheets: Easily cut to size, offering flexibility for specialized or small-batch operations.

Why Choose Braemar USA Diamond Lapping Film?

-

Superior Surface Quality:

First and foremost, our Diamond Lapping Film is engineered to achieve ultra-smooth finishes with minimal polishing steps. In other words, it’s ideal for critical applications where surface integrity and precision are paramount. -

Eco-Friendly Solution:

In addition, this film provides a greener, more sustainable alternative to traditional slurry-based processes. With no need for messy slurries or harsh chemicals, it ensures an environmentally responsible choice for both your workshop and the planet. -

Cost-Effective:

Thanks to its high durability and performance, Braemar USA’s Diamond Lapping Film reduces material costs and minimizes downtime. As a result, it delivers long-term savings, helping to streamline operations without compromising on quality. -

Precision Engineering:

Lastly, our film is manufactured to the highest standards, ensuring uniform diamond particle distribution and consistent performance with each use. Whether you’re finishing delicate optical components or robust industrial materials, this film guarantees exceptional results.

Industries Served:

-

Aerospace: Ideal for polishing turbine blades, landing gear components, and other high-precision aerospace parts.

-

Medical Devices: Perfect for polishing and finishing implants, surgical tools, and medical devices with stringent surface finish requirements.

-

Semiconductors: Ensures smooth, defect-free finishes for delicate semiconductor wafers.

-

Optical Manufacturing: Reliable for superfinishing optical lenses and mirrors to precise specifications.

-

Automotive: Used for polishing parts like valve seats, camshafts, and other high-precision automotive components.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

Always in stock - 6x6 sheet

1 mic - 3 mil

3 mic - 3 mil

6 mic - 3 mil

9 mic - 3 mil

15 mic - 3 mil

30 mic - 3 mil

45 mic - 3 mil

Item Number

5111156

3005253

3386471

3478963

3478971

3005287

3005290

Always in stock - 6x6 sheet :

1 mic - 3 mil

Item Number:

5111156

Always in stock - 6x6 sheet :

3 mic - 3 mil

Item Number:

3005253

Always in stock - 6x6 sheet :

6 mic - 3 mil

Item Number:

3386471

Always in stock - 6x6 sheet :

9 mic - 3 mil

Item Number:

3478963

Always in stock - 6x6 sheet :

15 mic - 3 mil

Item Number:

3478971

Always in stock - 6x6 sheet :

30 mic - 3 mil

Item Number:

3005287

Always in stock - 6x6 sheet :

45 mic - 3 mil

Item Number:

3005290