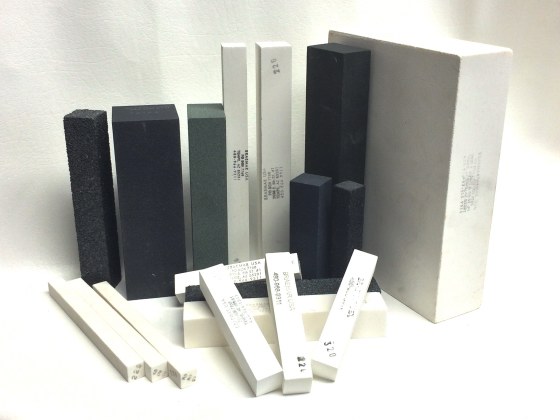

Dressing Sticks

Proper wheel conditioning is essential for maintaining free-cutting action, stable surface finishes, and longer wheel life when grinding with diamond or CBN wheels. Braemar USA Conditioning Sticks are engineered specifically to restore wheel performance by removing glazing, loading, and excess bond material from the wheel face.

Why Conditioning Matters

Over time, superabrasive wheels can become glazed or loaded. As a result, cutting efficiency drops while heat generation and chatter increase. By using the correct dressing (conditioning) stick, fresh abrasive points are exposed, allowing the wheel to cut freely again. Consequently, grinding stability and surface quality are restored.

Applications

These conditioning sticks are ideal for dressing resin-bond, metal-bond, and vitrified-bond diamond and CBN wheels used in:

-

Optical grinding and polishing

-

Ceramics and advanced composites

-

Sapphire, quartz, and glass

-

Carbide and tool grinding

-

Precision CNC and manual grinding operations

Features

-

Manufactured from high-quality aluminum oxide or silicon carbide, depending on the application

-

Formulated for free-cutting behavior with minimal loading

-

Available in multiple grits, bond grades, sizes, and shapes, including rectangular and square cross-sections

-

Designed for controlled bond removal without damaging the wheel structure

Key Benefits

-

Restores consistent wheel cutting performance

-

Extends diamond and CBN wheel life

-

Improves surface finish repeatability

-

Reduces grinding heat and vibration

-

Minimizes downtime for re-truing and re-conditioning

Sizing & Selection Guidance

For best results, select a conditioning stick slightly smaller than the wheel face or width. Additionally, match the grit and bond grade to your wheel and application:

-

Coarser grits for heavy-duty or metal-bond wheels

-

Finer grits for finishing wheels and precision applications

Usage Tips

Secure the wheel properly and run it at the recommended operating speed. Then, gently apply the conditioning stick across the wheel face in multiple light passes. Avoid excessive pressure. If coolant is used, maintain steady flow and clean debris from the wheel after dressing.

Request a quote today to optimize wheel life, improve grinding performance, and maintain consistent results with Braemar USA Conditioning (Dressing) Sticks for Diamond and CBN Wheels.

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

ITEM

STA/O220

STA/O320

STA/O600

STA/O800

STA22005056

ST006556

STA220118

ST862229H6VB

DESCRIPTION

0.750 X 0.750 X 4.000 220

0.750 X 0.750 X 4.000 320

0.750 X 0.750 X 4.000 600

0.750 X 0.750 X 6.000 800

0.500 X 0.500 X 6.000 220

0.500 X 0.500 X 6.000 220

1.000 X 1.000 X 8.000 220

8.500 X 6.000 X 2.000 220

PURPOSE

RESIN BOND 100-270 GRIT WHEELS

RESIN BOND 270-400 GRIT WHEELS

RESIN BOND 400-600 GRIT WHEELS

RESIN & METAL BOND 600-1200 GRIT WHEELS

METAL BOND 220 100-270 GRIT WHEELS

METAL BOND 220 140/300 GRIT WHEELS

RESIN BOND 100-270 GRIT WHEELS

RESIN & METAL BOND 100/270 GRIT WHEELS

ITEM:

STA/O220

DESCRIPTION:

0.750 X 0.750 X 4.000 220

PURPOSE:

RESIN BOND 100-270 GRIT WHEELS

ITEM:

STA/O320

DESCRIPTION:

0.750 X 0.750 X 4.000 320

PURPOSE:

RESIN BOND 270-400 GRIT WHEELS

ITEM:

STA/O600

DESCRIPTION:

0.750 X 0.750 X 4.000 600

PURPOSE:

RESIN BOND 400-600 GRIT WHEELS

ITEM:

STA/O800

DESCRIPTION:

0.750 X 0.750 X 6.000 800

PURPOSE:

RESIN & METAL BOND 600-1200 GRIT WHEELS

ITEM:

STA22005056

DESCRIPTION:

0.500 X 0.500 X 6.000 220

PURPOSE:

METAL BOND 220 100-270 GRIT WHEELS

ITEM:

ST006556

DESCRIPTION:

0.500 X 0.500 X 6.000 220

PURPOSE:

METAL BOND 220 140/300 GRIT WHEELS

ITEM:

STA220118

DESCRIPTION:

1.000 X 1.000 X 8.000 220

PURPOSE:

RESIN BOND 100-270 GRIT WHEELS

ITEM:

ST862229H6VB

DESCRIPTION:

8.500 X 6.000 X 2.000 220

PURPOSE:

RESIN & METAL BOND 100/270 GRIT WHEELS