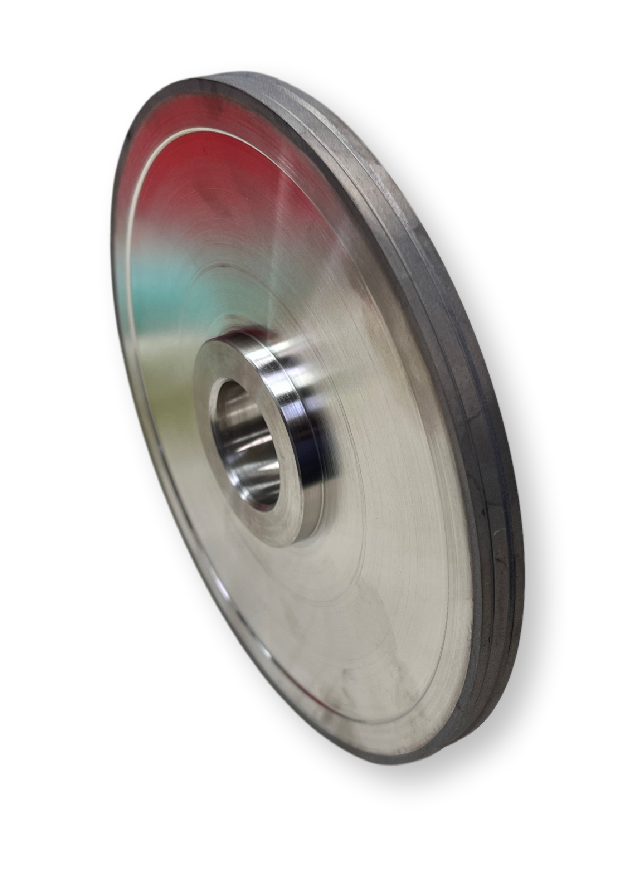

Electroplated Diamond Beveling Wheels

Braemar USA engineers Electroplated Diamond Beveling Wheels for high-precision chamfering, edge shaping, and bevel grinding of glass, quartz, sapphire, ceramics, and other brittle or advanced materials. Specifically, Braemar manufactures these wheels using a controlled single-layer electroplated diamond process. As a result, the wheels deliver aggressive cutting action, reduced heat generation, and excellent edge quality. Therefore, manufacturers rely on them for optical production, semiconductor processing, precision glass shops, and advanced materials fabrication.

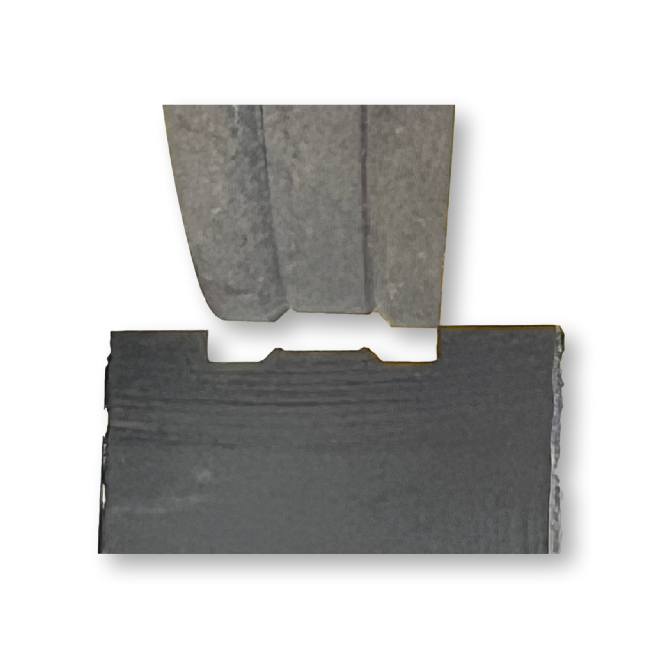

Braemar builds each wheel with uniform diamond exposure and a rigid steel core. Because of this design, the wheels maintain consistent bevel angles, smooth edge transitions, and long service life. In addition, operators can run them effectively on both manual and CNC beveling machines. Unlike conventional bonded wheels, Braemar’s electroplated beveling wheels retain their form without dressing. Consequently, production teams achieve tight tolerances and higher throughput with minimal downtime.

Key Features & Benefits

-

First, exposed electroplated diamond delivers fast, aggressive cutting

-

Moreover, true bevel geometry provides precise angle control and consistent profiles

-

Additionally, the single-layer abrasive design eliminates the need for dressing

-

As a result, cool cutting action reduces chipping, micro-fractures, and thermal stress

-

Furthermore, the wheels produce excellent surface finishes on glass, quartz, sapphire, ceramics, and composites

-

Meanwhile, rigid steel cores ensure stable, vibration-free grinding

-

Finally, the wheels integrate smoothly with CNC and manual edge-grinding systems

Applications

Manufacturers use these wheels for a wide range of beveling and edge-finishing tasks. For example, shops commonly apply them to:

-

Optical lenses and prisms

-

Quartz and fused silica components

-

Sapphire windows and substrates

-

Technical ceramics and brittle composites

-

Precision glass edges for displays, housings, and instrumentation

-

Semiconductor wafers, IR materials, and high-purity substrates

Industries Served

Accordingly, Braemar USA supplies electroplated beveling wheels to industries such as:

-

Optical fabrication

-

Semiconductor manufacturing

-

Aerospace and defense optics

-

Scientific instrumentation

-

Precision glass machining

-

Advanced materials engineering

Why Choose Braemar USA Electroplated Beveling Wheels?

Braemar USA combines a high-strength nickel bond with optimized diamond exposure to maximize performance. Because of this approach, customers achieve longer tool life and cleaner bevels. In addition, the wheels reduce micro-chipping, which improves downstream polishing efficiency. Consequently, operators maintain repeatable bevel geometry while improving thermal control. Ultimately, the wheels deliver stable, reliable performance at higher feed rates.

Braemar also offers custom bevel angles, edge profiles, arbor sizes, and grit selections. Therefore, customers can match each wheel precisely to their machines, materials, and production requirements.

Call (480) 966-9311 or Add to Quote for pricing.