Electroplated Diamond Mounted Cut Off Wheels

Electroplated Diamond Mounted Cut-Off Wheels – Braemar USA

Braemar USA Electroplated Diamond Mounted Cut-Off Wheels are engineered for precision cutting, slotting, notching, and trimming of the hardest technical materials used in modern manufacturing. Each wheel is plated with a single, uniform layer of premium synthetic diamond, providing an exceptionally sharp cutting edge and fast, free-cutting performance with minimal heat generation.

Designed for CNC machines, high-speed spindles, manual cut-off stations, and specialty precision equipment, these wheels deliver clean, accurate cuts in carbide, ceramics, glass, quartz, sapphire, composites, and other advanced materials where surface integrity is critical. The rigid steel or mandrel-mounted construction ensures stability at high RPMs and consistent geometry throughout the tool’s life.

Key Features & Benefits

-

Fast, Free-Cutting Action

Single-layer diamond plating provides immediate sharpness with no break-in period. -

High Dimensional Accuracy

Maintains wheel thickness, profile, and edge geometry for precision slotting and micro-cutting. -

Reduced Heat & Chipping

Electroplated structure minimizes friction—ideal for brittle, heat-sensitive materials. -

Rigid Mounted Design

Mandrel-mounted wheels deliver exceptional stability and low vibration at high surface speeds. -

Long-Lasting Performance

Uniform diamond exposure maximizes tool life while ensuring smooth, consistent cutting.

Materials Cut

-

Carbide

-

Ceramics (Alumina, Zirconia, Technical Ceramics)

-

Glass, Quartz, Fused Silica

-

Sapphire & Optical Crystals

-

Graphite & Carbon Composites

-

Hard Steels (non-ferrous)

-

Semiconductor & electronic substrates

Applications

-

Precision cutting and trimming

-

Slotting & grooving

-

Notching & part separation

-

Optical materials processing

-

Semiconductor wafer preparation

-

Toolmaking & carbide cutting operations

-

Micro-machining and fine-detail cut-off work

Industries Served

-

Optics manufacturing

-

Semiconductor & electronics

-

Carbide tool production

-

Aerospace & defense machining

-

Medical device manufacturing

-

Advanced ceramics & composites fabrication

-

Research labs & prototyping facilities

Why Choose Braemar USA Electroplated Cut-Off Wheels?

Braemar USA uses tightly controlled diamond sizing, proprietary low-temperature plating, and precision-machined mandrels to ensure exceptional quality and consistency. Each wheel is engineered for maximum cutting speed, clean edge quality, and dependable performance in demanding production environments.

Call (480) 966-9311 or Add to Quote for pricing.

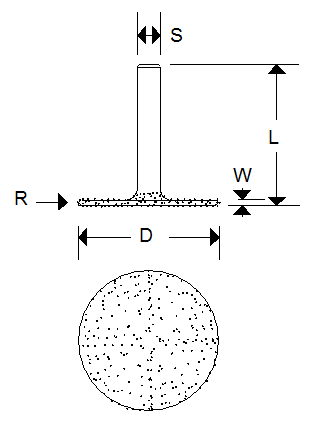

Specifications

ITEM#

DPMCSS0240A

DPMCSS0250B

DPMCSS0250A

6233-2

6232-2

0153288

DPMCSS1000A

DPMCSS1000C

DPMCSS1500A

DPMCSS1500B

6233-5

62382

DPMCSS2000A

D

0.240

0.250

0.250

0.750

0.750

1.000

1.000

1.000

1.500

1.500

1.500

2.000

2.000

W

0.022

0.040

0.030

0.060

0.060

0.060

0.090

0.080

0.090

0.090

0.070

0.060

0.090

S

0.125

0.125

0.250

0.250

0.125

0.125

0.250

0.250

0.250

0.500

0.250

0.250

0.250

L

1.885

1.885

1.885

1.500

1.500

1.400

3.000

2.000

3.000

2.000

1.500

3.000

3.000

R

0.010

0.015

0.015

0.030

0.030

0.010

0.030 (4) SLOTS

0.030

0.030

0.030

0.035

0.030

0.030

GRIT

200/230

100/120

100/120

140/170

140/170

100/120

060/080

060/080

060/080

060/080

100/120

040/060

060/080

ITEM#:

DPMCSS0240A

D:

0.240

W:

0.022

S:

0.125

L:

1.885

R:

0.010

GRIT:

200/230

ITEM#:

DPMCSS0250B

D:

0.250

W:

0.040

S:

0.125

L:

1.885

R:

0.015

GRIT:

100/120

ITEM#:

DPMCSS0250A

D:

0.250

W:

0.030

S:

0.250

L:

1.885

R:

0.015

GRIT:

100/120

ITEM#:

6233-2

D:

0.750

W:

0.060

S:

0.250

L:

1.500

R:

0.030

GRIT:

140/170

ITEM#:

6232-2

D:

0.750

W:

0.060

S:

0.125

L:

1.500

R:

0.030

GRIT:

140/170

ITEM#:

0153288

D:

1.000

W:

0.060

S:

0.125

L:

1.400

R:

0.010

GRIT:

100/120

ITEM#:

DPMCSS1000A

D:

1.000

W:

0.090

S:

0.250

L:

3.000

R:

0.030 (4) SLOTS

GRIT:

060/080

ITEM#:

DPMCSS1000C

D:

1.000

W:

0.080

S:

0.250

L:

2.000

R:

0.030

GRIT:

060/080

ITEM#:

DPMCSS1500A

D:

1.500

W:

0.090

S:

0.250

L:

3.000

R:

0.030

GRIT:

060/080

ITEM#:

DPMCSS1500B

D:

1.500

W:

0.090

S:

0.500

L:

2.000

R:

0.030

GRIT:

060/080

ITEM#:

6233-5

D:

1.500

W:

0.070

S:

0.250

L:

1.500

R:

0.035

GRIT:

100/120

ITEM#:

62382

D:

2.000

W:

0.060

S:

0.250

L:

3.000

R:

0.030

GRIT:

040/060

ITEM#:

DPMCSS2000A

D:

2.000

W:

0.090

S:

0.250

L:

3.000

R:

0.030

GRIT:

060/080