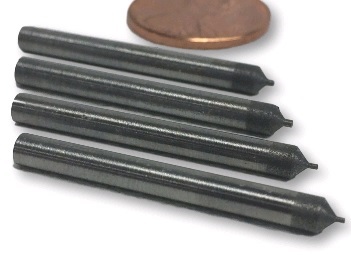

Metal Bond Diamond Micro Reamers

Metal Bond Diamond Micro Reamers are engineered for ultra-precision hole sizing, polishing, and micro-finishing in the hardest and most brittle materials used in optics, semiconductors, ceramics, aerospace components, instrumentation, and advanced technical manufacturing. Built using a dense, long-wear metal bond matrix that securely retains diamond particles, these micro reamers deliver exceptional dimensional accuracy, tool life, and surface integrity—even in micron-level tolerances.

Designed for CNC machining centers, micro-drilling stations, spindle-driven mandrels, and high-accuracy manual setups, Braemar micro reamers provide clean, round, straight holes with minimal chipping, tight size control, and smooth internal walls. Each tool is manufactured to exacting engineering standards to ensure consistent performance in demanding production environments.

Key Performance Features

1. Long-Life Metal Bond Construction

-

High-strength metal bond securely locks in diamond grit

-

Exceptional wear resistance for extended tool life

-

Maintains geometry even under continuous production loads

-

Ideal for high-precision micro-finishing applications

2. Precision Hole Sizing & Micro-Finishing

-

Produces extremely round and dimensionally stable bores

-

Smooths internal walls after drilling or EDM

-

Excellent for optical apertures, ferrule polishing, sapphire/quartz micro-holes, and ceramic components

3. Clean Cutting in Hard & Brittle Materials

Engineered for materials where edge quality is critical:

-

Sapphire

-

Fused silica

-

Quartz

-

Ceramics (alumina, zirconia, machinable ceramic)

-

Glass and technical glasses

-

Carbide

-

Silicon carbide (SiC)

-

Ferrites and composites

4. Ultra-Fine Diamond Finishes Available

-

Grit sizes from coarse to micron grades

-

Achieves extremely tight size tolerances

-

Final polishing options for high-optical-quality apertures

5. Customizable Geometry

Braemar USA offers complete customization:

-

Diameter sizes (micro-diameter down to sub-millimeter)

-

Overall length and shank sizes

-

Diamond length and exposure

-

Bond hardness and diamond concentration

-

Coolant channels or special coatings

Applications

Braemar metal bond diamond micro reamers are widely used in:

-

Optical manufacturing – lens apertures, precision optical bores

-

Semiconductor processing – micro-holes, wafer components

-

Ceramic & sapphire machining – tight-tolerance finishing

-

Medical & instrumentation – micro-channels, precision ports

-

Aerospace & defense – miniature components requiring high accuracy

-

Research labs & advanced engineering – prototype and specialty materials

Why Choose Braemar USA?

Braemar USA delivers industry-leading diamond tool engineering with:

-

Strict geometric tolerances

-

Controlled diamond exposure and bond formulation

-

Long, predictable tool life

-

Fast production lead times

-

U.S.-based support for technical applications

When precision, surface quality, and reliability matter, Braemar USA Metal Bond Diamond Micro Reamers provide unmatched performance across advanced material machining.

Call (480) 966-9311 or Add to Quote for pricing.

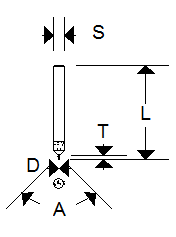

Specifications

(D) DIAMETER

0.020"

0.025"

0.030"

0.035"

0.040"

(T) LENGTH

0.060"

0.060"

0.060"

0.060"

0.060"

(S) SHANK

1.000"

1.000"

1.000"

1.000"

1.000"

(A) INCL ANGLE

90°

90°

90°

90°

90°

GRIT

600

600

600

600

600

(D) DIAMETER:

0.020"

(T) LENGTH:

0.060"

(S) SHANK:

1.000"

(A) INCL ANGLE:

90°

GRIT:

600

(D) DIAMETER:

0.025"

(T) LENGTH:

0.060"

(S) SHANK:

1.000"

(A) INCL ANGLE:

90°

GRIT:

600

(D) DIAMETER:

0.030"

(T) LENGTH:

0.060"

(S) SHANK:

1.000"

(A) INCL ANGLE:

90°

GRIT:

600

(D) DIAMETER:

0.035"

(T) LENGTH:

0.060"

(S) SHANK:

1.000"

(A) INCL ANGLE:

90°

GRIT:

600

(D) DIAMETER:

0.040"

(T) LENGTH:

0.060"

(S) SHANK:

1.000"

(A) INCL ANGLE:

90°

GRIT:

600