Metal Bond Diamond Micro Threading Tools

Metal Bond Diamond Micro Threading Tools are engineered for ultra-fine thread generation in the hardest, most brittle, and most abrasive materials. Designed for applications where conventional carbide or HSS tools fail, these micro threading tools deliver exceptional edge strength, long tool life, and precision form accuracy—ideal for advanced manufacturing environments that require consistent micron-level detail.

Built using premium synthetic diamond held in a wear-resistant metal bond matrix, Braemar micro threading tools maintain their geometry under high loads, high RPM, and continuous production cycles. Whether you are machining sapphire, ceramics, quartz, glass, silicon carbide, or technical composites, these tools provide unmatched stability and long-life performance.

Engineered for Ultra-Fine Thread Accuracy

Braemar’s tightly controlled diamond concentration and metal bond structure ensure:

-

Crisp, well-defined thread profiles

-

Minimal edge rounding during long production runs

-

Stable cutting forces for consistent pitch and depth

-

Reduced micro-chipping in brittle materials

These characteristics make Braemar tools ideal for high-tolerance optical, semiconductor, aerospace, medical, and micro-mechanical components.

Long-Life Metal Bond Performance

The durable metal bond matrix provides:

-

Extremely high diamond retention

-

Excellent resistance to wear and glazing

-

Superior form stability at high spindle speeds

-

Predictable, uniform tool wear

This results in longer tool life compared to resin bond or electroplated styles—especially in hard, abrasive materials.

Materials Commonly Machined

Braemar Metal Bond Diamond Micro Threading Tools excel in:

-

Sapphire

-

Alumina & advanced ceramics

-

Quartz & fused silica

-

Glass

-

Silicon carbide (SiC)

-

Carbide

-

Technical composites

Ideal for both manual precision setups and CNC micro-machining systems.

Applications

These specialty threading tools are critical for:

-

Optical components and housings

-

Semiconductor packages and micro-channels

-

Medical device components

-

Watchmaking & micro-mechanical parts

-

Ultra-precision prototyping

-

High-accuracy research and engineering

Custom Geometry Options

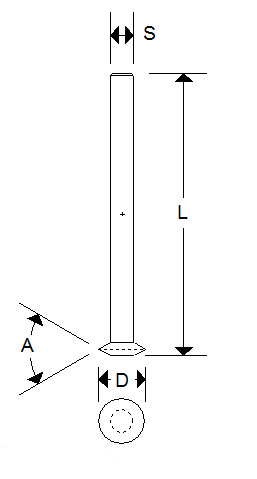

Braemar USA manufactures micro threading tools to your exact specifications:

-

Pitch, profile, and included angle

-

Diamond grit size (coarse to micron finishing)

-

Tool diameter and shank size

-

Single-point or multi-form profiles

-

Internal or external threading tools

Engineered per job requirements, ensuring maximum precision and long-term performance.

Why Choose Braemar USA Micro Threading Tools?

-

Industry-trusted metal bond technology

-

Consistent thread quality in extremely hard materials

-

Extended tool life and reduced downtime

-

Micron-level accuracy for demanding production

-

Custom geometries available for OEM and high-precision applications

Braemar USA delivers advanced micro-machining tools that support optical fabrication, semiconductor engineering, micro-medical component manufacturing, and research facilities worldwide.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

(D) DIAMETER

0.100"

0.100"

0.100"

0.140"

0.175"

0.175"

0.200"

0.375"

0.500"

(S) SHANK

0.062"

0.062"

0.062"

0.093"

0.093"

0.093"

0.187"

0.125"

0.250"

(L) LENGTH

2.000"

2.000"

2.000"

2.000"

2.000"

2.000"

2.000"

2.000"

2.500"

(A) INCL ANGLE

60°

60°

60°

60°

60°

60°

90°

60°

60°

(M) MATERIAL

CERAMIC

CERAMIC

CERAMIC

CERAMIC

CERAMIC

CERAMIC

CERAMIC

CERAMIC

CERAMIC

GRIT

170/200

300/330

170/200

200/230

200/230

200/230

200/230

200/230

200/230

(D) DIAMETER :

0.100"

(S) SHANK:

0.062"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

170/200

(D) DIAMETER :

0.100"

(S) SHANK:

0.062"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

300/330

(D) DIAMETER :

0.100"

(S) SHANK:

0.062"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

170/200

(D) DIAMETER :

0.140"

(S) SHANK:

0.093"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

200/230

(D) DIAMETER :

0.175"

(S) SHANK:

0.093"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

200/230

(D) DIAMETER :

0.175"

(S) SHANK:

0.093"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

200/230

(D) DIAMETER :

0.200"

(S) SHANK:

0.187"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

90°

(M) MATERIAL:

CERAMIC

GRIT:

200/230

(D) DIAMETER :

0.375"

(S) SHANK:

0.125"

(L) LENGTH:

2.000"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

200/230

(D) DIAMETER :

0.500"

(S) SHANK:

0.250"

(L) LENGTH:

2.500"

(A) INCL ANGLE:

60°

(M) MATERIAL:

CERAMIC

GRIT:

200/230