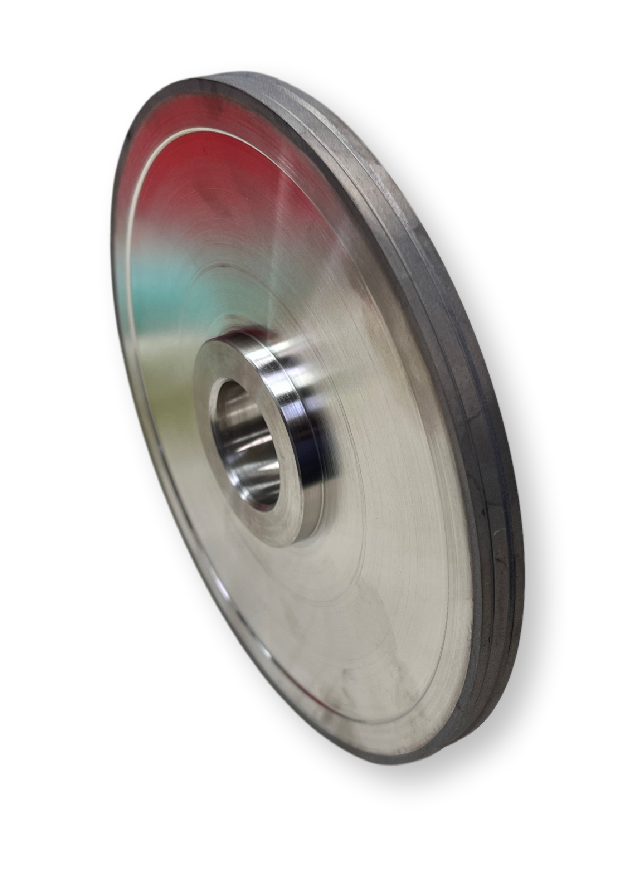

Optical Generating Tools Mounted

Braemar’s Metal bond optical generating tools shape and generate precision optical surfaces with exceptional form accuracy and repeatability. Manufacturers build these tools using a rigid, sintered metal bond matrix that securely holds diamond abrasive, allowing controlled material removal on demanding optical substrates.

Engineers use metal bond generating tools to create spherical, aspheric, and freeform geometries during the early stages of optical fabrication. Because the metal bond resists wear and thermal distortion, the tool maintains its profile throughout long production cycles.

Key Design Features

-

The metal bond matrix provides high stiffness and prevents wheel deformation.

-

Uniform diamond grit distribution delivers consistent cutting action.

-

Engineered porosity improves coolant flow and chip evacuation.

-

Optimized bond hardness balances material removal and surface integrity.

As a result, these tools generate accurate optical forms while minimizing subsurface damage.

Applications in Optical Manufacturing

Manufacturers rely on metal bond optical generating tools to:

-

Generate aspheric and freeform optical surfaces

-

Rough and semi-finish spherical lenses

-

Pre-shape optical molds and precision blanks

-

Produce custom optics that require tight form tolerances

CNC optical generators use synchronized tool and part motion to create the intended surface geometry. The rigid metal bond supports aggressive feeds without sacrificing accuracy.

Performance Advantages

Metal bond optical generating tools outperform softer bond systems in high-load generating operations.

-

The metal bond extends tool life and reduces replacement frequency.

-

Stable geometry ensures repeatable form accuracy from part to part.

-

Efficient cutting action reduces cycle time and improves throughput.

-

Controlled grinding limits subsurface damage, improving downstream polishing results.

Because of these advantages, optical manufacturers select metal bond tools for both prototype development and production environments.

Material Compatibility

Metal bond generating tools machine a wide range of optical materials, including:

-

Optical glass (fused silica, borosilicate)

-

Advanced ceramics

-

Crystalline materials

-

Sapphire and other hard substrates

The diamond abrasive cuts efficiently across varying hardness levels, making these tools highly versatile.

Why Choose Metal Bond for Optical Generating?

Metal bond optical generating tools deliver superior rigidity, durability, and form stability compared to resin or vitrified alternatives. When optical surface accuracy, repeatability, and process control matter, metal bond tools provide a reliable foundation for precision optical manufacturing.

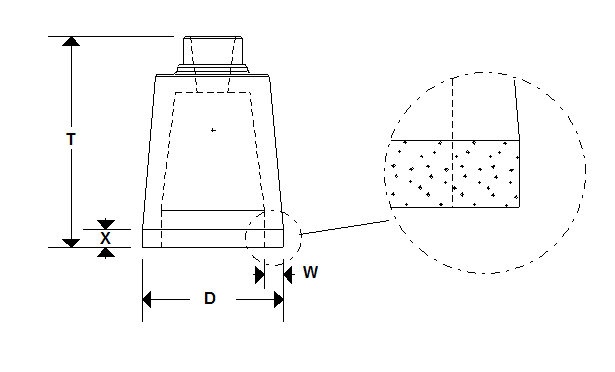

Flat Surfacing Optical Generating tools

Flat Surfacing Optical Generating Tools are precision diamond-abrasive tools designed for generating flat and planar surfaces on optical components during the rough-grinding stage. These tools establish accurate flatness and parallelism prior to fine grinding and polishing, making them critical for high-quality optical production.

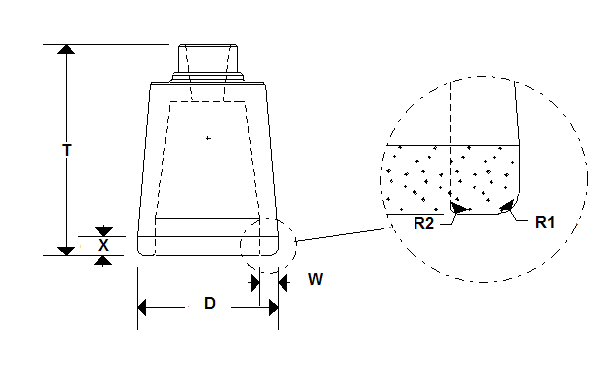

Radius Profiling Optical Generating tools

Radius Profiling Optical Generating Tools are precision diamond-abrasive tools designed to generate defined radii and complex curved profiles on optical components during the generating or rough-grinding stage. These tools are used to accurately shape lens surfaces and profiles before fine grinding and polishing, ensuring consistent geometry and repeatable results.

Call (480) 966-9311 or Add to Quote for pricing.