11V9 Diamond Cup Wheels

11V9 Diamond Cup Wheels for CNC Tool Grinding

11V9 Diamond Cup Wheels from Braemar USA deliver accurate and steady grinding on CNC tool grinders and automated systems. These resin bond 11V9 diamond wheels cut cleanly and hold their shape during use. As a result, they produce smooth surface finishes and consistent tool geometry.

Because of this stable performance, operators often use these wheels for fluting, gashing, relief grinding, and small-tool shaping. In addition, the wheels work well in both production and regrind applications.

Resin Bond for Cool and Stable Grinding

The resin bond design helps control heat during grinding. While the wheel runs, the bond releases dull diamond grains and exposes new, sharp cutting edges. This process keeps the wheel cutting efficiently throughout its service life.

As a result, operators see:

-

Lower grinding temperatures

-

Less burning and edge damage

-

Cleaner cutting action

-

More consistent surface finishes

Because heat stays under control, these wheels perform well on carbide, ceramics, quartz, fused silica, glass, and composite materials.

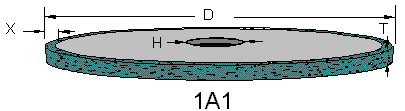

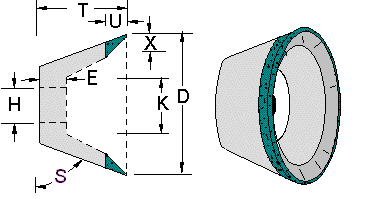

11V9 Cup Shape for Accurate Tool Grinding

The 11V9 cup wheel shape adds support at the grinding zone. This added stiffness reduces wheel flex and improves control during precision grinding. As a result, operators can grind small tools with greater confidence.

Typical applications include:

-

Flute grinding

-

Gash and clearance-angle grinding

-

Relief grinding

-

Small-tool and micro-tool work

-

Step drills, end mills, and reamers

Because the wheel holds its form, tight tolerances are easier to maintain. At the same time, sharp edges and fine details remain intact.

Consistent Performance in Production Environments

Braemar USA 11V9 Diamond Cup Wheels are built for daily production use. They grind smoothly and deliver repeatable results over long runs. Even as workloads increase, performance stays predictable.

Key benefits include:

-

Steady wear with reliable wheel shape

-

Smooth grinding with low vibration

-

Strong edge retention

-

Repeatable results across long cycles

-

Reduced chipping and improved finishes

In addition, these wheels run well on ANCA, Walter, Rollomatic, Saacke, Schneeberger, EWAG, and other CNC tool-and-cutter grinders.

Suitable for Hard and Brittle Materials

11V9 Diamond Cup Wheels are designed to grind difficult materials accurately. For example, they are commonly used on:

-

Tungsten carbide

-

Technical and advanced ceramics

-

Glass, fused silica, and quartz

-

PCD and PCBN

-

Advanced composites

With stable form and good heat control, Braemar USA 11V9 Diamond Cup Wheels meet the accuracy and surface-finish demands of modern CNC tool grinding.

SDDD Alternative Truing Method

Truing Stick for Diamond & CBN Resin Bond Wheels

“A new simple way”

more information on our SDDD Truing Stick

.

Call (480) 966-9311 or Add to Quote for pricing.

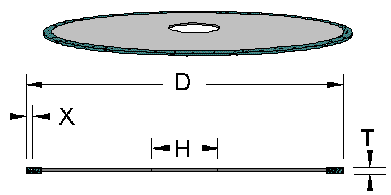

Specifications

(D) WHEEL DIAMETER

1.000

1.500

2.000

3.000

3.000

3.750

5.000

(T) WHEEL HEIGHT

0.875

0.875

1.000

1.250

1.250

1.500

1.750

(H) ARBOR HOLE

0.250

0.375

0.375

0.375

1.250

1.250

1.250

GRIT SIZE

60/100

60/100/220/320

60/100/220/320

60/100/220/320

60/100/220/320

60/100/220/320

60/100/220/320

(D) WHEEL DIAMETER:

1.000

(T) WHEEL HEIGHT :

0.875

(H) ARBOR HOLE:

0.250

GRIT SIZE:

60/100

(D) WHEEL DIAMETER:

1.500

(T) WHEEL HEIGHT :

0.875

(H) ARBOR HOLE:

0.375

GRIT SIZE:

60/100/220/320

(D) WHEEL DIAMETER:

2.000

(T) WHEEL HEIGHT :

1.000

(H) ARBOR HOLE:

0.375

GRIT SIZE:

60/100/220/320

(D) WHEEL DIAMETER:

3.000

(T) WHEEL HEIGHT :

1.250

(H) ARBOR HOLE:

0.375

GRIT SIZE:

60/100/220/320

(D) WHEEL DIAMETER:

3.000

(T) WHEEL HEIGHT :

1.250

(H) ARBOR HOLE:

1.250

GRIT SIZE:

60/100/220/320

(D) WHEEL DIAMETER:

3.750

(T) WHEEL HEIGHT :

1.500

(H) ARBOR HOLE:

1.250

GRIT SIZE:

60/100/220/320

(D) WHEEL DIAMETER:

5.000

(T) WHEEL HEIGHT :

1.750

(H) ARBOR HOLE:

1.250

GRIT SIZE:

60/100/220/320