Wheel Flanges 1A8F

Precision Diamond Wheel Flanges are specially engineered mounting components designed to securely hold diamond and CBN grinding wheels on a machine spindle. Proper flange systems are critical because diamond wheels are very precise and sensitive to imbalance, vibration, or uneven clamping, which can drastically reduce wheel life and surface finish quality.

Key Features of Precision Wheel Flanges:

- High concentricity & runout accuracy – Typically ground to within a few microns to ensure perfect wheel rotation.

- Balanced construction – Some flanges come pre-balanced or with balance weights to minimize vibration at high spindle speeds.

- Rigid clamping – Distributes clamping pressure evenly across the wheel to prevent cracks or distortion.

- Precision-ground contact surfaces – Ensure secure wheel mounting and repeatability after wheel changes.

- Materials – Usually made from hardened alloy steel or aluminum alloys (for lighter setups).

Types of Precision Flanges:

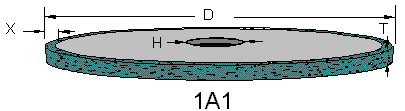

- Standard precision flanges – For most diamond/CBN wheels, for dicing and sloting.

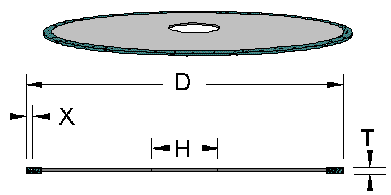

- Reducer flanges that have a built in bushing to hold a wheel with a large ID that needs to be mounted on a smaller diameter spindle of mount.

Benefits:

- Maximizes wheel life.

- Improves grinding accuracy and surface finish.

- Reduces spindle and bearing wear from vibration.

- Increases safety by ensuring secure clamping at high RPMs.

These flanges are commonly used in surface grinders, cylindrical grinders, tool & cutter grinders, and CNC precision grinding machines.

Call (480) 966-9311 or Add to Quote for pricing.