Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

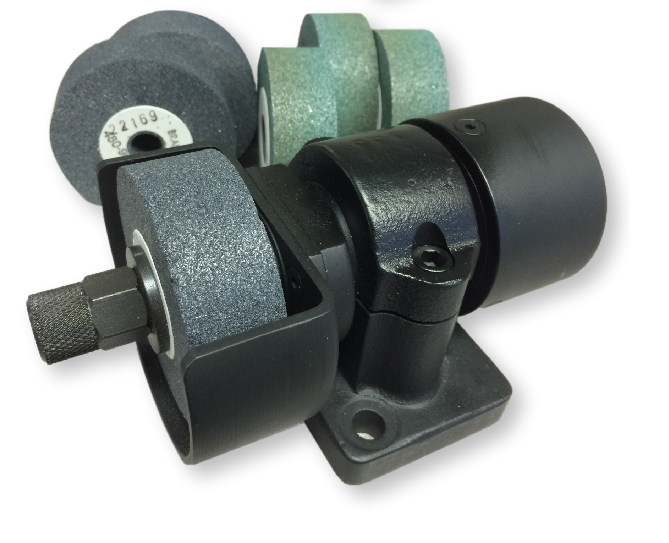

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

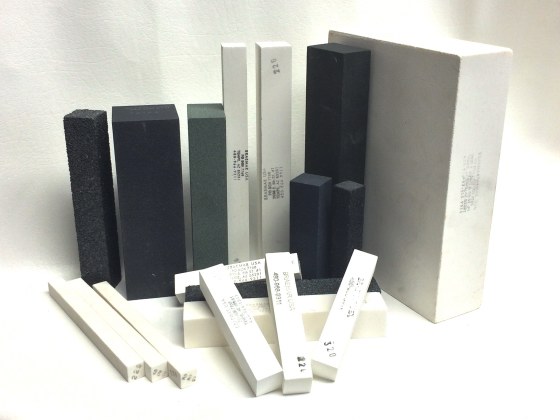

Resin Bond Diamond Wheels

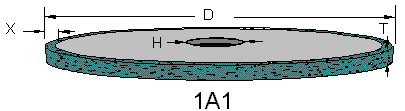

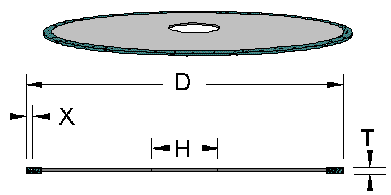

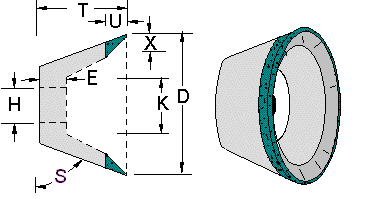

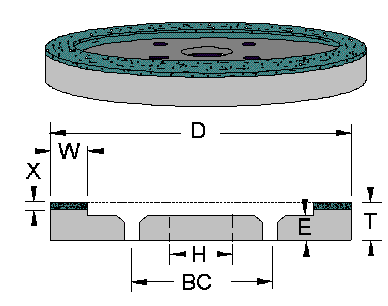

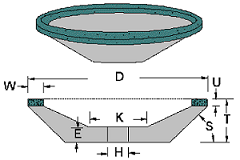

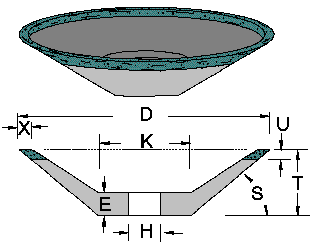

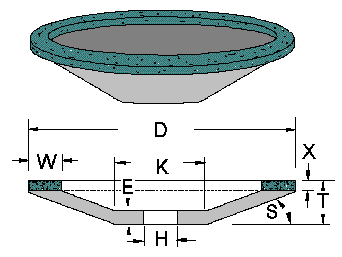

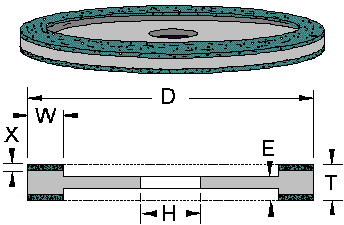

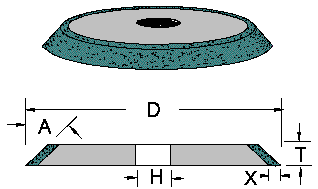

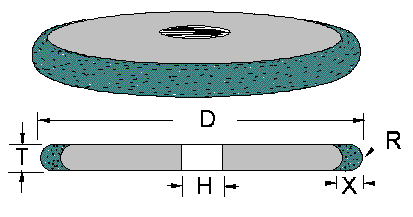

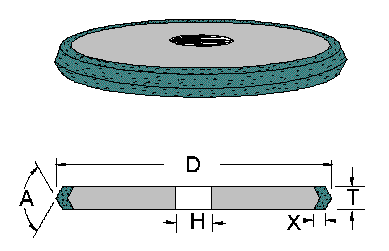

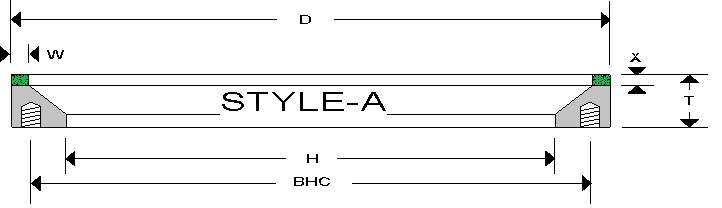

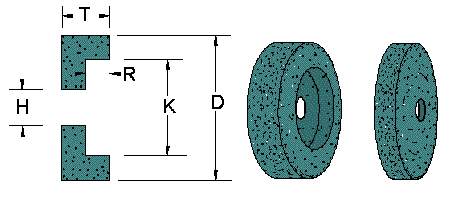

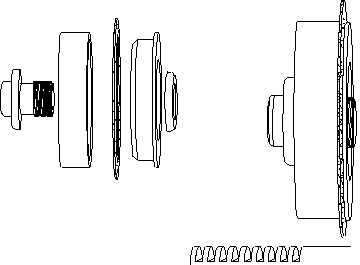

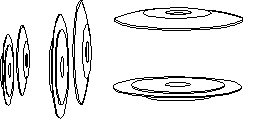

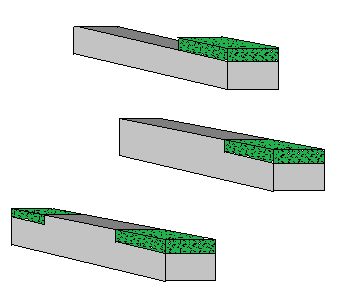

Resin Bond Diamond Wheels for precision grinding where surface quality, edge retention, and consistency matter. Our advanced resin systems balance cutting speed, wheel integrity, and tool life. This makes them ideal for grinding carbide, ceramics, sapphire, optical glass, and advanced composites. Resin bond technology delivers a fast, cool-cutting grind that reduces burning, heat damage, and micro-cracking. This is essential when working with brittle or temperature-sensitive materials. The controlled resin matrix exposes fresh diamond edges at a steady rate, keeping cutting points sharp and grinding efficiency high. Braemar USA resin formulations produce fine, scratch-free finishes for optics, semiconductors, carbide tool production, and other precision fields. High diamond retention keeps diamonds locked in place, preserves wheel geometry, and extends usable life. Fewer changeovers, tighter tolerances, and improved throughput follow. These wheels also hold shape across complex profiles such as 1A1, 11V9, 12V9, 6A2, 1V1, slotting wheels, and form wheels—perfect for CNC tool grinding and intricate profile work. We offer resin bond grades for every grinding need: Standard for general use, High-Strength for heavy stock removal, Heat-Resistant for high-temperature operations, and our Premium “Super Bond” for maximum retention and long life. Resin bond’s forgiving nature lowers vibration, protects spindle bearings, reduces machine wear, and improves consistency. With efficient cutting, predictable wear, and strong diamond utilization, Braemar USA resin bond wheels produce more parts per wheel and lower your total cost per grind.