Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

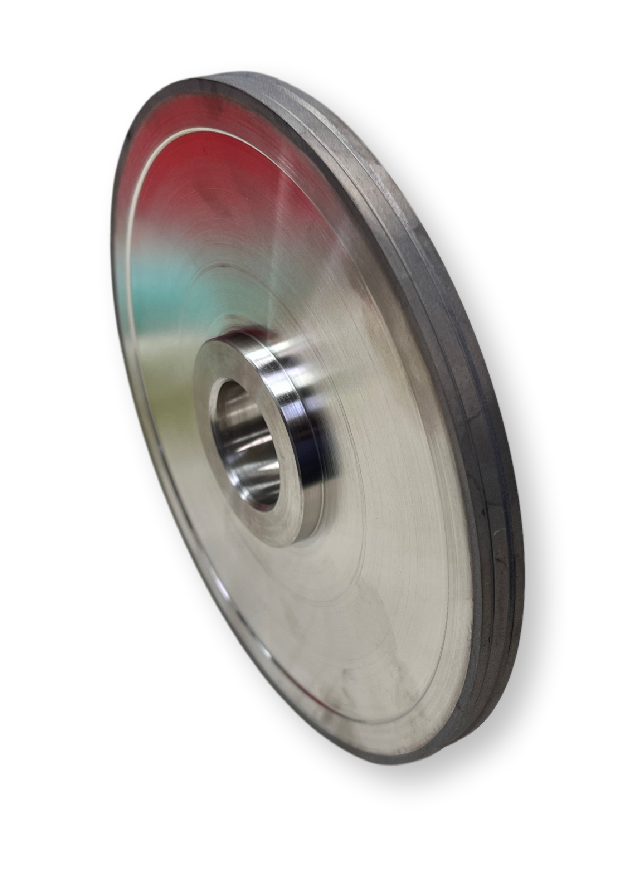

Electroplated Diamond Wheels

BGSUSA Electroplated Diamond Wheels deliver aggressive, free-cutting performance on the hardest and most brittle materials. The single-layer nickel bond exposes every diamond grain, giving each wheel maximum sharpness and fast stock removal. This design makes plated wheels ideal for shaping, slotting, edging, and precision contour grinding where crisp geometry and minimal heat are critical. They excel in optical machining, advanced ceramics, carbide toolmaking, and composite manufacturing. Electroplated wheels cut efficiently because the nickel matrix holds a single layer of high-grade diamond abrasive. The exposed structure produces immediate, aggressive cutting from the first pass and maintains excellent form on tight-tolerance profiles. These wheels generate clean edges with minimal micro-chipping and reduced heat, allowing both wet and dry grinding. Their sharp, open cutting action makes them the preferred choice for fine-detail work, tool fabrication, and precision finishing. BGSUSA electroplated wheels perform exceptionally on hard and brittle materials such as carbide, ceramics, quartz, fused silica, glass, optical substrates, graphite, carbon fiber, composites, stone, sapphire, and other technical materials. They support a wide range of applications including profile grinding, CNC tool grinding, optical edge grinding, slotting, cutoff work, jig grinding, and precision ID/OD contouring. Users gain the advantages of maximum diamond exposure, fast cool-cutting action, precise geometry, and long tool life in specialized operations. BGSUSA also offers full custom engineering. Options include diameters from micro-tool sizes to large CNC wheels, custom shapes such as 1A1, 1A8, 14A1, 11V9, 12V9, 1EE1, 1FF1, 6A2C, and complex profiling forms. Diamond grit sizes range from coarse to micron finish, with single- or multi-step electroplating available. Mandrels and arbor sizes can be matched to any OEM machine.