Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

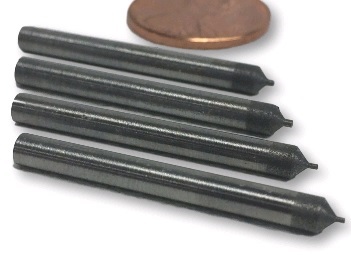

Metal Bond Diamond Tools

Braemar USA’s metal bond diamond tools deliver the durability, tight tolerances, and consistent performance required in demanding grinding environments. We engineer each tool with advanced metallic matrices and premium diamond to ensure strong form holding, low wear, and high cutting efficiency on the hardest materials. Manufacturers rely on these tools for grinding carbide, ceramics, technical glass, sapphire, quartz, ferrite, composites, and precision optical substrates. Whether you need heavy stock removal or ultra-fine finishing, Braemar metal bond products provide stable performance, long tool life, and reliable accuracy in high-production settings. Aerospace companies, semiconductor wafer processors, optical lens manufacturers, carbide toolmakers, advanced ceramic producers, automotive suppliers, composite fabricators, and research facilities depend on Braemar tools to maintain quality under constant load. Our long-wearing metal bonds reduce downtime, improve dimensional consistency, and support modern automated grinding systems. Braemar engineers each metal bond tool to match your specific application. You can select any grit size—from coarse to micron-level finishes—adjust diamond concentration levels, tune bond hardness, or specify a custom metallic matrix. We also design tool geometry, precision profiles, coolant channels, internal coolant ports, arbor sizes, and reinforced bodies to enhance performance. These engineered features improve chip evacuation, maintain steady diamond exposure, reduce heat, and extend tool life even at higher feed rates. With decades of experience serving the optical, semiconductor, aerospace, carbide, and ceramics industries, Braemar USA builds every tool to strict performance standards. Our production team maintains tight dimensional accuracy, uniform material composition, and consistent wheel-to-wheel behavior from prototype through full-scale manufacturing. Because we operate in the United States, we offer fast lead times, quick technical support, and precise application-specific guidance. If your job requires a unique geometry, specialty grit size, custom coolant configuration, or tailored metal bond formulation, Braemar USA can design and manufacture a tool to your exact specifications. We deliver custom metal bond tools with short lead times and tightly controlled tolerances.