Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

- Diamond Threaded Countersinks

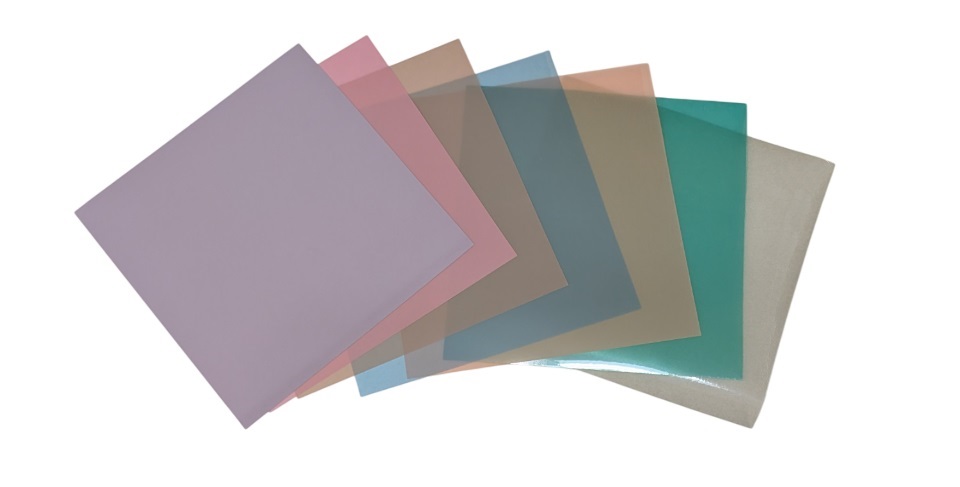

Diamond Lapping Compound

Diamond Lapping Compound is engineered for precision polishing, ultra-fine finishing, and controlled material removal on the hardest and most wear-resistant materials. Formulated with premium synthetic diamond and a highly stable carrier, our compound delivers consistent cutting rates, uniform surface finishes, and exceptional process control across demanding industrial, tooling, and optical applications. Available in a full range of micron sizes—from aggressive stock-removal grades to ultra-fine polishing formulations—Braemar USA Diamond Lapping Compound ensures repeatable performance whether you’re finishing carbide tools, preparing optical surfaces, or smoothing precision metal components. Engineered for High-Precision Finishing Our compound features tightly graded synthetic diamond particles suspended in a clean, uniform oil- or water-based carrier. This allows for: Uniform scratch patterns Predictable material removal Excellent surface integrity Reduced sub-surface damage Perfect for carbide dies, molds, ceramics, sapphire, hardened steels, and precision optical materials. Consistent, Fast Cutting Action Braemar USA Diamond Lapping Compounds maintain their cutting efficiency throughout the process: Sharp, blocky diamond crystals Even dispersion in the carrier Won’t dry out or separate Stable performance during manual or machine lapping Ideal for diamond plates, cast-iron laps, copper laps, ceramic laps, and specialty polishing tools.