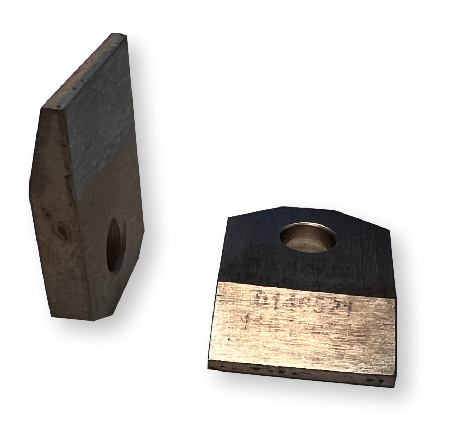

Blade style Fliesen Diamond Dressers

Blade-Style Fliesen Diamond Dressers – Precision Dressing Tools from Braemar USA

Braemar USA Blade-Style Fliesen Diamond Dressers are engineered for fast, accurate, and economical dressing of vitrified, resin, and metal-bond grinding wheels. Built with premium, sharp natural or synthetic diamond embedded along the blade edge, these dressers deliver consistent form accuracy while restoring wheel sharpness, opening the grain structure, and maintaining optimal grinding performance.

Designed for production grinding environments where repeatable geometry and long service life are essential, Braemar Fliesen dressers provide a reliable solution for truing flat surfaces, dressing radii, and maintaining wheel face perpendicularity on internal, external, and surface grinding machines.

High-Performance Dressing Construction

Braemar USA Fliesen Diamond Dressers are manufactured using high-grade diamond and a durable metal matrix that ensures:

-

Sharp, exposed diamond cutting edges for clean dressing passes

-

Uniform diamond distribution for precise wheel conditioning

-

High thermal and mechanical stability in demanding operations

-

Longer dresser life compared to single-point or cluster alternatives

Each blade is optimized for rigidity, ensuring controlled, chatter-free dressing cycles.

Advantages of Blade-Style Fliesen Dressers

-

Ideal for flat and form dressing across a wide range of wheel specifications

-

Improved wheel cutting action—restores sharpness and reduces grinding forces

-

Superior surface finish on carbide, ceramics, HSS, tool steels, and advanced alloys

-

Cost-effective tool life for high-volume production

-

Consistent wheel geometry for better dimensional accuracy and reduced scrap

These characteristics make Braemar’s blade-type diamond dressers an excellent choice for tool rooms, production grinding lines, and CNC grinding operations.

Applications

Blade-Style Fliesen Diamond Dressers are used in:

-

Surface grinding

-

Cylindrical grinding (OD/ID)

-

Centerless grinding

-

Tool & cutter grinding

-

Precision form grinding

Industries served include aerospace, automotive, carbide tooling, medical devices, optics, and general precision machining.

Available Options

Braemar USA offers custom and standard Fliesen dresser specifications:

-

Blade widths, lengths, and diamond layer heights

-

Natural or synthetic diamond

-

Custom diamond concentrations

-

Special radii, angles, and multi-layer constructions

Custom-engineered dressers can be manufactured to match your exact wheel size, dressing profile, and grinding parameters.

Why Choose Braemar USA?

Braemar USA provides high-precision diamond dressing tools built for reliability, profile stability, and long service life. With decades of engineering experience in diamond tooling, Braemar supports production facilities with tools that reduce downtime, improve wheel performance, and deliver consistent, repeatable dressing results.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

HOLDER

SHANK

SHANK

INSERT

INSERT

TYPE

0.437 SHK

0.437 SHK TAPERED

0.125 X 0.400 X 0.200

0.125 X 0.400 X 0.200

MOUNT

1.750 SHK

1.750 SHK

0.250" HOLE

0.250" HOLE

SIZE

0.33 CT.

0.33 CT.

0.33 CT.

0.33 CT.

NUMBER OF

DIAMONDS

3

3

3

3

HOLDER:

SHANK

TYPE:

0.437 SHK

MOUNT:

1.750 SHK

SIZE:

0.33 CT.

NUMBER OF

DIAMONDS:

3

HOLDER:

SHANK

TYPE:

0.437 SHK TAPERED

MOUNT:

1.750 SHK

SIZE:

0.33 CT.

NUMBER OF

DIAMONDS:

3

HOLDER:

INSERT

TYPE:

0.125 X 0.400 X 0.200

MOUNT:

0.250" HOLE

SIZE:

0.33 CT.

NUMBER OF

DIAMONDS:

3

HOLDER:

INSERT

TYPE:

0.125 X 0.400 X 0.200

MOUNT:

0.250" HOLE

SIZE:

0.33 CT.

NUMBER OF

DIAMONDS:

3