Cluster Diamond Dressers

Cluster Diamond Dressers

High-Performance Multi-Point Dressing for Precision Grinding Wheels

Cluster Diamond Dressers are engineered for heavy-duty truing and dressing of grinding wheels where long service life, stable form accuracy, and consistent performance are essential. Built using multiple, tightly mounted natural or synthetic diamond points, cluster dressers deliver robust, repeatable dressing action that outperforms traditional single-point tools in demanding production environments.

Designed for vitrified, resin, and some metal-bond grinding wheels, these multi-stone diamond dressers provide exceptional durability and grinding wheel conditioning—ideal for OD grinding, ID grinding, surface grinding, centerless grinding, and automated dressing systems.

Why Choose a Braemar Cluster Diamond Dresser?

1. Extremely Long Life & High Durability

Cluster dressers contain multiple diamond points embedded in a compact head.

• Distributes dressing forces across several diamonds

• Reduces shock loading and point wear

• Maintains performance even on hard or large-diameter wheels

This design provides significantly longer tool life compared to single-point dressers.

2. Consistent Wheel Truing & Dressing

The multi-point configuration ensures predictable and uniform contact with the grinding wheel, resulting in:

• Smooth wheel conditioning

• Stable wheel geometry

• Reduced chipping or glazing

• Improved grinding efficiency

Ideal for applications requiring repeatable precision across long production runs.

3. Reduced Downtime & Improved Productivity

Because multiple diamond tips work simultaneously, cluster dressers:

• Require less frequent tool indexing

• Provide consistent dressing over extended periods

• Increase uptime on centerless, cylindrical, and surface grinders

This makes them well suited for automated or high-volume manufacturing.

4. Suitable for a Wide Range of Grinding Wheels

Braemar cluster dressers are compatible with:

• Vitrified grinding wheels

• Resin bond wheels

• Aluminum oxide and silicon carbide wheels

They are commonly used for:

• OD/ID grinding

• Centerless grinding

• Surface grinding

• Form grinding

• Production lines using CNC and manual machines

Construction & Technical Features

• Multiple natural or synthetic diamond points

• Precision-ground shanks and mounting tolerances

• High-strength bonding for diamond retention

• Available in block, cone, and custom configurations

• Suitable for reciprocating or plunge dressing

• Custom diamond patterns and head sizes available

Braemar can engineer custom cluster dressers based on wheel size, dressing aggressiveness, CNC requirements, and production volume.

Industries That Use Cluster Diamond Dressers

• Automotive component grinding

• Bearing manufacturing

• Aerospace precision grinding

• Tool & cutter grinding

• Steel and alloy production

• General machining and finishing shops

Any operation that needs stable, long-life wheel conditioning benefits from Braemar’s cluster dresser technology.

Optimize Your Grinding Performance

Braemar USA Cluster Diamond Dressers deliver rugged reliability, long service life, and consistent dressing performance. Whether you’re conditioning wheels on a centerless grinder or maintaining form accuracy in a high-production line, these dressers provide the durability and precision your operation demands.

Call (480) 966-9311 or Add to Quote for pricing.

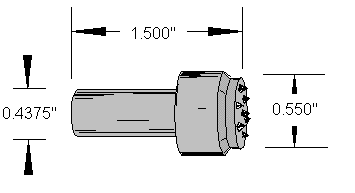

Specifications

SHANK

0.437"

0.437"

0.437"

0.375"

0.437"

LENGTH

1.500"

1.500"

1.500"

1.500"

1.500"

DIAMONDS

5

5

7

7

7

CT WEIGHT

0.75

1.25

0.75

1.25

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

5

CT WEIGHT:

0.75

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

5

CT WEIGHT:

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

0.75

SHANK:

0.375"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

1.25