Cluster Diamond Tools

Cluster diamond tools are multi point diamond dressing tools used for truing conventional grinding wheels. Instead of a single large diamond, they contain a group (or cluster) of small diamond points or stones mounted together, either on the surface of the tool or layered in the metal section.

They are mainly used for dressing and truing grinding wheels in these situations:

- High material removal is needed from the grinding wheel.

- Large grinding wheels need frequent conditioning.

- A robust tool is required for heavy-duty applications.

Key Features of Cluster Diamond Tools:

- Multiple diamonds working at once → reduces wear compared to single-point dressers.

- Longer tool life since dressing load is distributed among several diamonds.

- Aggressive dressing action, making them suitable for opening up grinding wheels with hard or dense bonds.

- Can be made in different shapes (cylindrical, blade, chisel, or custom forms).

- Used on both conventional abrasive wheels (aluminum oxide, silicon carbide)

Common Types:

- Cluster Stick Dressers – A bar with multiple diamond particles bonded to its surface.

- Cluster Disc/Blade Tools – Diamond clusters arranged in a line for wide, fast dressing.

- Random Cluster Tools – Multiple small diamonds randomly set into the tool face.

- Typically in a 5 or 7 stone pattern

Applications:

- Truing large surface grinding wheels.

- Opening up resin or vitrified bond wheels.

- Situations where a single-point dresser would wear too fast or not remove enough material.

- Heavy-duty grinding of steels, cast irons, and hard alloys.

Stock Items below, custom tools can be made to order.

Call (480) 966-9311 or Add to Quote for pricing.

Specifications

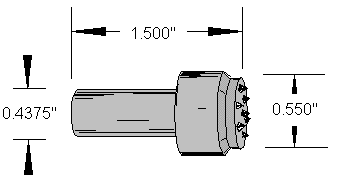

SHANK

0.437"

0.437"

0.437"

0.375"

0.437"

LENGTH

1.500"

1.500"

1.500"

1.500"

1.500"

DIAMONDS

5

5

7

7

7

CT WEIGHT

0.75

1.25

0.75

1.25

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

5

CT WEIGHT:

0.75

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

5

CT WEIGHT:

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

0.75

SHANK:

0.375"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

1.25

SHANK:

0.437"

LENGTH:

1.500"

DIAMONDS:

7

CT WEIGHT:

1.25