F-Series Radius Dressing Tools

F-Series Radius Dressing Tools are engineered for precision truing and profiling of grinding wheels used in high-accuracy production environments. Built with premium natural and synthetic diamond, each F-Series tool is designed to maintain exact radii, produce clean wheel profiles, and deliver long, predictable service life in demanding grinding applications.

Ideal for forming concave, convex, and full-radius profiles on resin bond, vitrified bond, CBN, and diamond grinding wheels, these tools provide exceptional geometric accuracy with minimal operator effort. Whether you’re shaping wheels for carbide tool manufacturing, optical grinding, ceramics, or high-precision steel components, Braemar F-Series dressers ensure consistent results and smooth cutting performance.

Precision-Engineered Radius Dressing Performance

The F-Series diamond dresser line features:

• Consistent Radius Accuracy

Every tool is precisely manufactured to exact radius specifications, ensuring uniform wheel profiles and repeatable results in CNC or manual grinding setups.

• High-Quality Diamond Cutting Points

Using tightly graded premium diamond, F-Series tools provide clean cutting, stable performance, and long life—maintaining profile geometry even under heavy use.

• Smooth Wheel Surface Finish

The diamond tip produces a refined wheel surface that improves cutting efficiency, reduces wheel loading, and enhances finish quality on the workpiece.

• Durable Steel or Carbide Tool Bodies

Engineered for strength and rigidity to ensure stable contact, vibration reduction, and accurate wheel shape generation.

Applications

F-Series Radius Dressing Tools are commonly used for:

-

Carbide tool manufacturing (end mills, drills, form tools)

-

Precision OD/ID grinding

-

Optical lens and glass grinding wheel radiusing

-

Ceramics, quartz, and sapphire wheel profiling

-

CNC form grinding and production grinding cells

-

Maintenance dressing on vitrified or resin bond wheels

These tools excel anywhere accurate wheel geometry and repeatable radii are required.

Why Choose Braemar USA F-Series?

-

Tight radius tolerances for precision tool grinding

-

Extended service life with high-grade diamond construction

-

Consistent dressing action for stable grinding performance

-

Custom radii and lengths available to match OEM machines

-

Trusted by tool manufacturers, optical shops, and advanced material processors

Braemar USA provides industry-leading dressing solutions engineered for reliability, accuracy, and long-term performance in high-precision grinding environments.

Call (480) 966-9311 or Add to Quote for pricing.

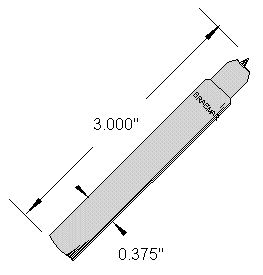

Specifications

SHANK

0.375"

0.375"

0.375"

0.375"

0.375"

0.375"

0.375"

LENGTH

3.000"

3.000"

3.000"

3.000"

3.000"

3.000"

3.000"

RADIUS

0.010"

0.015"

0.020"

0.025"

0.031"

0.062"

0.125"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.010"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.015"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.020"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.025"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.031"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.062"

SHANK:

0.375"

LENGTH:

3.000"

RADIUS:

0.125"