Heald Diamond Dresser

Heald Diamond Dresser – Braemar USA | Long Product Page Version

Heald Diamond Dresser engineered by Braemar USA for Heald internal grinding machines, delivering precise wheel truing, clean dressing action, and repeatable form restoration for tight-tolerance ID grinding. This Heald-compatible diamond dresser provides the accuracy, stability, and durability required to maintain microscopic bore precision across demanding production environments, making it a reliable, high-performance replacement for OEM Heald dressers.

Precision Dressing for Heald Internal Grinders

Heald grinding machines depend on stable wheel geometry to achieve ultra-tight ID tolerances. Therefore, each Braemar Heald Diamond Dresser is manufactured with exacting dimensions, premium-grade diamond, and high-strength shank construction. This ensures predictable dressing behavior, consistent wheel form, and optimal grinding efficiency throughout the entire production cycle.

To support all common Heald setups, Braemar produces each dresser with precision-ground carbide or steel shanks that resist vibration and heavy dressing pressure. Additionally, the diamond is carefully selected for orientation, size, and exposure to achieve clean, controlled dressing passes on metal bond, resin bond, vitrified, CBN, and electroplated diamond ID wheels.

OEM-Compatible Geometry for Accurate ID Wheel Restoration

Every Braemar Heald Diamond Dresser is engineered to match original Heald geometry. As a result, operators can maintain accurate wheel form without modifying machine offsets or compensation. This precise compatibility enables the dresser to:

-

True ID grinding wheels quickly

-

Restore wheel concentricity

-

Refresh sharp abrasive exposure

-

Maintain bore-size accuracy even during long production runs

These capabilities are essential for grinding carbide, ceramics, hardened steels, quartz, advanced composites, and other difficult materials commonly machined on Heald systems.

Premium Diamond for Superior Surface Finish & Stability

Braemar uses high-quality natural or synthetic diamond mounted with tight control over angle and seating depth. This delivers:

-

Crisp, stable dressing passes

-

Improved coolant penetration

-

Sharper wheel structure

-

Reduced loading and glazing

-

Better wheel life and surface finish

The robust diamond-retention system prevents crystal movement under shock loads, ensuring long service life in heavy-duty production environments.

Rigid Shank Construction for High-Load Dressing

Heald ID grinding applications generate significant dressing forces. To maintain full stability, each dresser is built with a rigid carbide or steel shank. This construction:

-

Minimizes vibration

-

Ensures predictable form accuracy

-

Supports repeatable dressing cycles

-

Enhances performance under continuous duty

As a result, operators experience more consistent wheel behavior across long shifts and complex ID grinding programs.

Used Across Precision Manufacturing Industries

Braemar USA Heald Diamond Dressers are trusted in environments where accuracy is mission-critical, including:

-

Aerospace machining

-

Precision carbide grinding

-

Ceramic component manufacturing

-

Automotive internal grinding

-

Advanced materials processing

-

High-accuracy toolrooms and R&D labs

From routine wheel maintenance to aggressive form correction, these dressers deliver stable, repeatable dressing performance.

A Proven Replacement for OEM Heald Dressers

Because Braemar maintains tight tolerances, controlled diamond exposure, and U.S.-based engineering support, these dressers serve as a dependable, cost-effective alternative to OEM Heald dressing tools. Operators benefit from:

-

Longer tool life

-

Repeatable dressing accuracy

-

Cleaner wheel structure

-

Enhanced grinding consistency

-

Reduced scrap and rework

Engineered for Accuracy, Durability & Value

For precise, stable, and long-lasting ID wheel dressing on Heald internal grinders, Braemar USA Heald Diamond Dressers provide the performance demanded by today’s high-precision manufacturers. With superior geometry, high-grade diamond, and robust construction, they deliver long-term reliability and unmatched value

Call (480) 966-9311 or Add to Quote for pricing.

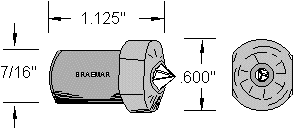

Specifications

SHANK

0.437"

0.437"

0.437"

0.437"

0.437"

LENGTH

1.125"

1.125"

1.125"

1.125"

1.125"

HEAD

0.600"

0.600"

0.600"

0.600"

0.600"

SIZE

0.25 CT.

0.33 CT.

0.50 CT.

0.75 CT.

1.00 CT.

SHANK:

0.437"

LENGTH:

1.125"

HEAD:

0.600"

SIZE:

0.25 CT.

SHANK:

0.437"

LENGTH:

1.125"

HEAD:

0.600"

SIZE:

0.33 CT.

SHANK:

0.437"

LENGTH:

1.125"

HEAD:

0.600"

SIZE:

0.50 CT.

SHANK:

0.437"

LENGTH:

1.125"

HEAD:

0.600"

SIZE:

0.75 CT.

SHANK:

0.437"

LENGTH:

1.125"

HEAD:

0.600"

SIZE:

1.00 CT.