J & L Diamond Dressers

J & L Diamond Dressers – Precision Truing Tools from Braemar USA

J & L Diamond Dressers are engineered for accurate, reliable dressing of grinding wheels used in precision machining, tool rooms, and production environments. Designed with a hardened steel shank and a carefully selected natural or synthetic diamond point, these dressers deliver clean, sharp wheel profiles essential for maintaining consistent grinding performance.

Whether you’re restoring wheel geometry, opening a loaded wheel surface, or preparing a fresh cutting face, J & L dressers offer the stability, durability, and precision demanded by high-accuracy grinding operations.

High-Accuracy Wheel Truing & Dressing

J & L Diamond Dressers are optimized for:

-

Truing vitrified, resin, and some metal-bonded grinding wheels

-

Restoring wheel form and cutting geometry

-

Removing glazing and opening the abrasive structure

-

Producing sharper cutting action and cooler grinding

Each dresser is manufactured to maintain rigid control over:

-

Diamond orientation

-

Shank concentricity

-

Tool center height

-

Effective radius and point sharpness

This ensures predictable, repeatable dressing results even under demanding shop conditions.

Engineered for Production and Toolroom Grinding

Braemar USA J & L dressers are ideal for:

-

Surface grinders

-

Cylindrical grinders

-

Tool & cutter grinders

-

OD/ID operations requiring precise wheel conditioning

-

Shops using high-performance aluminum oxide or silicon carbide wheels

Available in multiple diamond point sizes and geometries, these dressers support both rough dressing and ultra-fine finishing of grinding wheels.

Long Tool Life & Consistent Performance

Braemar selects premium diamond grades for J & L dressers to maximize:

-

Wear resistance

-

Shock durability

-

Stable dressing angles

-

Extended tool life in repetitive dressing cycles

The result is a dressing tool that maintains its form longer, reducing downtime and improving wheel quality throughout its lifespan.

Why Choose Braemar USA J & L Diamond Dressers?

-

Precision-machined shanks for stability

-

Premium natural or synthetic diamond selection

-

Excellent form retention, even in tough dressing conditions

-

Suitable for manual or CNC dressing systems

-

Made for consistent, dependable wheel conditioning

-

Supports high-tolerance grinding operations across multiple industries

Braemar USA provides consistent quality and engineering control to ensure your grinding wheels deliver maximum cutting efficiency and surface finish.

Call (480) 966-9311 or Add to Quote for pricing.

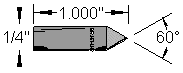

Specifications

SHANK

0.250"

0.250"

LENGTH

1.000"

1.000"

SIZE

0.07-0.08 CT

0.07-0.08 CT

QUALITY

STANDARD

SELECT

SHANK:

0.250"

LENGTH:

1.000"

SIZE:

0.07-0.08 CT

QUALITY:

STANDARD

SHANK:

0.250"

LENGTH:

1.000"

SIZE:

0.07-0.08 CT

QUALITY:

SELECT