XLO Excello Diamond Tools

XLO Excello Diamond Tools – Precision Dressing & Truing Solutions | Braemar USA

XLO Excello Diamond Tools are engineered for exceptional accuracy in dressing and truing grinding wheels used in high-precision production environments. Manufactured with premium natural and synthetic diamond, these Excello-style dressers ensure clean, consistent wheel conditioning, sharp cutting action, and repeatable performance on vitrified, resin, and metal-bond grinding wheels.

XLO Excello tools are trusted in applications requiring tight tolerances, stable form accuracy, and extended wheel life, making them a preferred solution for toolrooms, aerospace machining, automotive precision grinding, bearing production, and high-accuracy OD/ID grinding systems.

Engineered for High-Accuracy Wheel Dressing

Braemar’s XLO Excello diamond tools provide:

-

Sharp, well-supported diamond point geometry for clean wheel conditioning

-

Stable form control to maintain wheel radius, profile, and surface integrity

-

Consistent diamond exposure for predictable dressing performance

-

Long tool life through optimized diamond placement and support

-

Reduced loading and glazing for better wheel cutting efficiency

Each tool is manufactured with strict geometric control to ensure reliable, repeatable results in production setups.

Ideal for Precision Grinding Applications

XLO Excello Diamond Tools are designed for:

-

OD/ID cylindrical grinding

-

Surface grinding

-

Centerless grinding

-

Tool room maintenance

-

High-precision form correction

-

Dressing vitrified, resin, and metal-bond wheels

Whether you are restoring wheel shape, producing a sharp cutting face, or preparing a wheel for profile grinding, Braemar’s XLO tools deliver consistent and stable performance.

Braemar USA Quality & Performance

As a trusted U.S.–based diamond tool manufacturer, Braemar USA provides:

-

Precision-engineered diamond dressers built to OEM standards

-

Reliable diamond quality with secure, stable placement

-

Tools designed for long life in high-duty industrial environments

-

Support for custom geometries and special-purpose dressing tools

Braemar ensures every XLO Excello diamond tool meets the highest standards for accuracy, strength, and consistent dressing performance.

Applications & Industries

-

Aerospace component grinding

-

Automotive precision grinding

-

Bearing manufacturing

-

Tool grinding shops

-

CNC and manual OD/ID grinders

-

Production lines using vitrified or resin wheels

Why Choose Braemar USA XLO Excello Diamond Tools?

-

Exceptional value and dependable performance

-

OEM-quality diamond selection and support

-

Precision dressing for tighter tolerances

-

Longer wheel life through cleaner truing

-

Available in standard and custom configurations

Call (480) 966-9311 or Add to Quote for pricing.

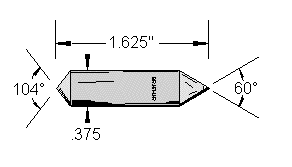

Specifications

ITEM NUMBER

DDT0150

DDT0155

DDT0160

DDT0165

DDT0170

DIAMOND GRADE

STANDARD

SELECT

A-GRADE

AA-GRADE

AAA-GRADE

DIAMOND SIZE

.07-.08 PT

.07-.08 PT

.08-.09 PT

.08-.09 PT

.09-.10 PT

ITEM NUMBER:

DDT0150

DIAMOND GRADE:

STANDARD

DIAMOND SIZE :

.07-.08 PT

ITEM NUMBER:

DDT0155

DIAMOND GRADE:

SELECT

DIAMOND SIZE :

.07-.08 PT

ITEM NUMBER:

DDT0160

DIAMOND GRADE:

A-GRADE

DIAMOND SIZE :

.08-.09 PT

ITEM NUMBER:

DDT0165

DIAMOND GRADE:

AA-GRADE

DIAMOND SIZE :

.08-.09 PT

ITEM NUMBER:

DDT0170

DIAMOND GRADE:

AAA-GRADE

DIAMOND SIZE :

.09-.10 PT