Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

Resin bond CBN wheels

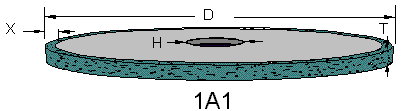

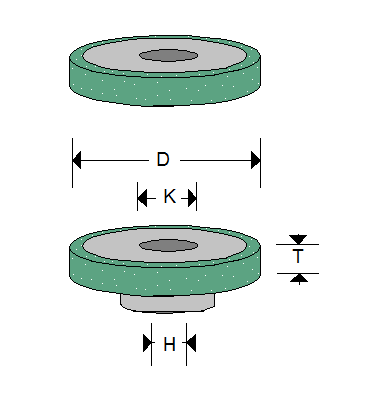

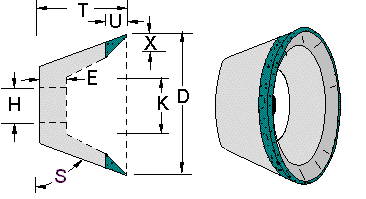

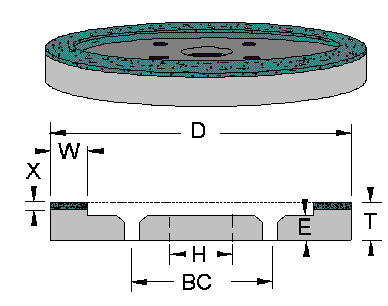

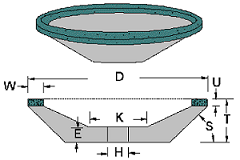

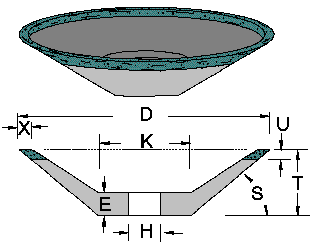

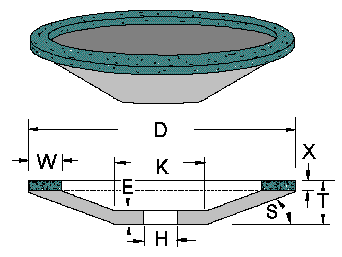

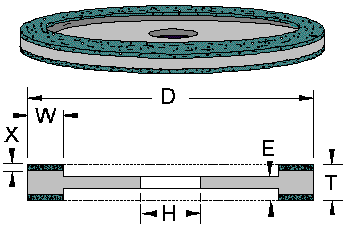

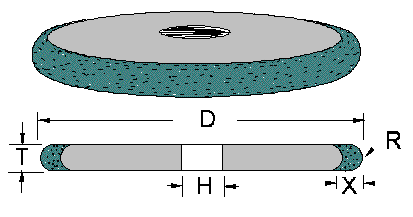

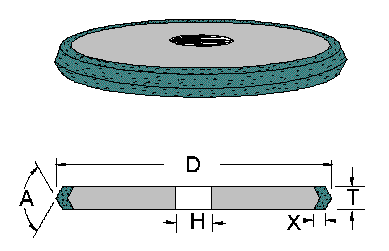

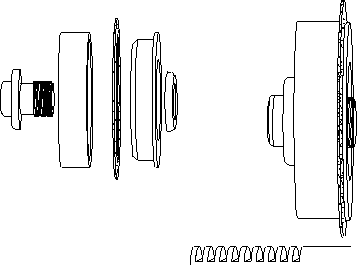

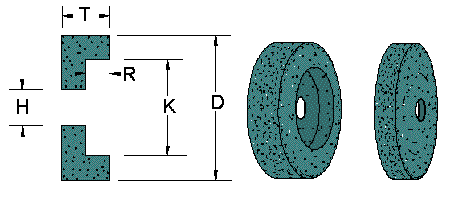

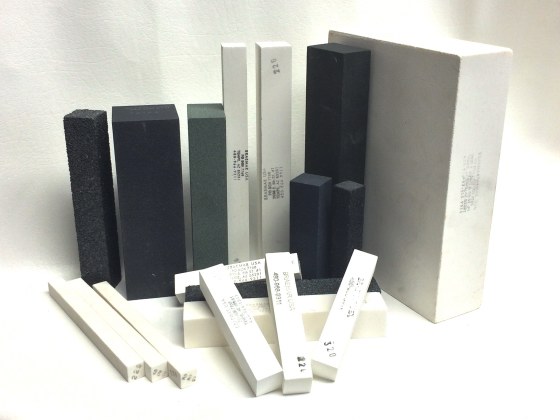

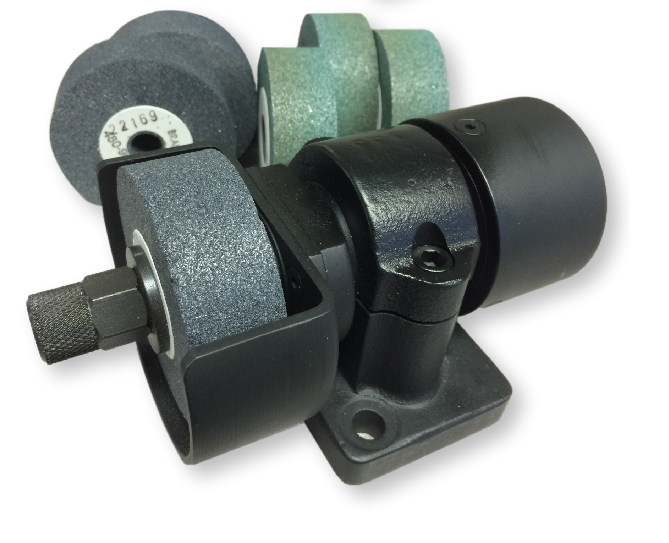

CBN resin bond wheels deliver high-performance grinding on hardened steels and high-alloy materials. The resin bond creates a fast, cool-cutting action that keeps CBN sharp, making these wheels a top choice for precision tool grinding and high-accuracy production. CBN outperforms other abrasives on ferrous metals because it does not react with iron, so it grinds HSS, cobalt steels, tool steels, powder-metal grades, bearing steels, and nickel alloys with ease. The resin matrix breaks down in a controlled way and constantly reveals fresh CBN edges, allowing the wheel to cut aggressively from start to finish. Its natural cushioning absorbs grinding forces, lowers friction, and prevents burning, cracking, and distortion—especially on thin or heat-sensitive profiles. These wheels produce low surface roughness, hold sharp edges, and maintain stable geometry, making them ideal for flute grinding, sharpening, form grinding, and fine finishing. They wear predictably, keep their cutting action consistent, shorten cycle times, and reduce dressing needs, all of which help maintain part quality in automated grinding cells. Braemar’s advanced resin systems, including “Super Bond,” hold wheel form under heavy pressure, long passes, and complex shapes like 1A1, 11V9, 12V9, and 6A2. CBN resin wheels perform best with coolant for maximum life and finish, but they still work well for light dry-grinding operations.