Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

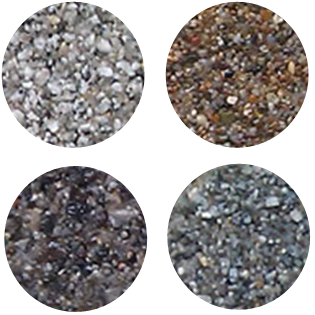

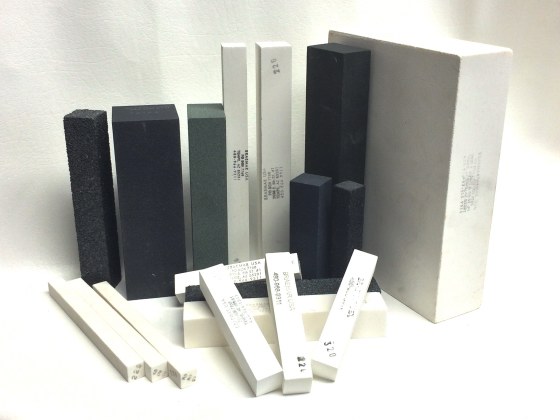

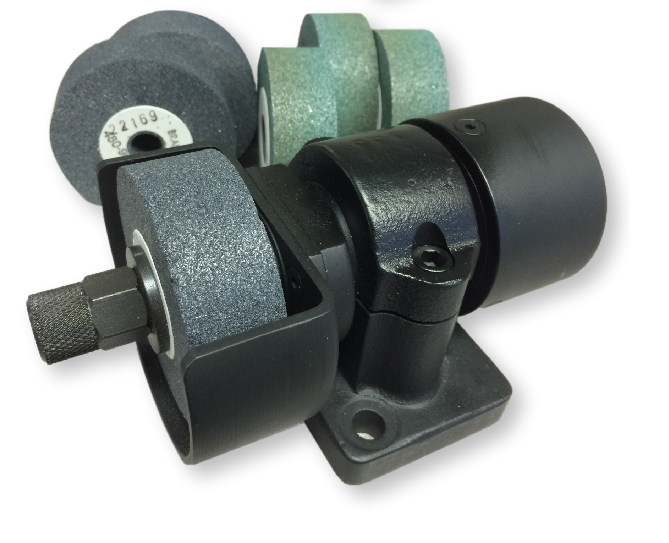

Resin bond CBN wheels

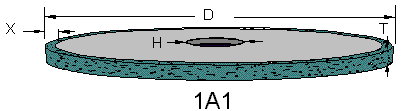

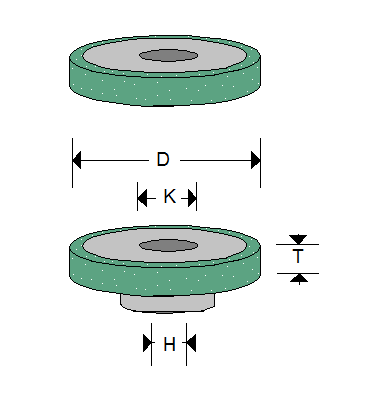

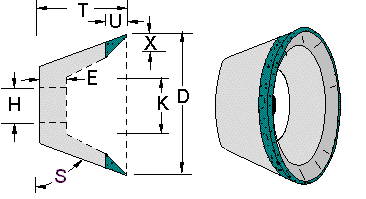

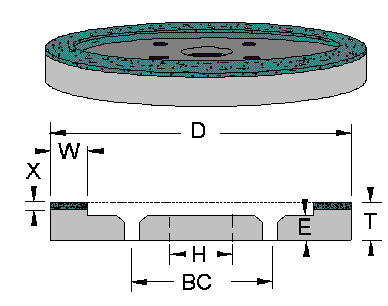

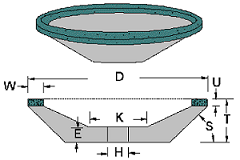

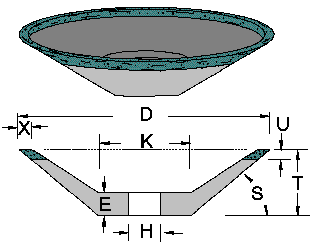

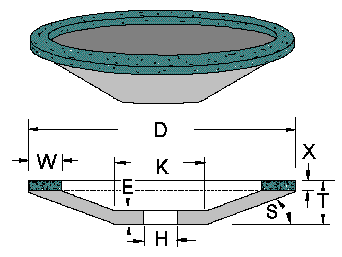

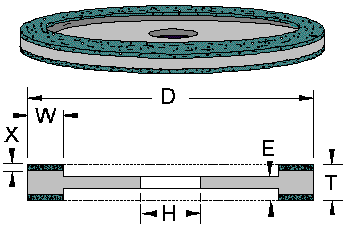

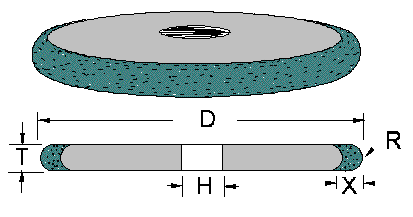

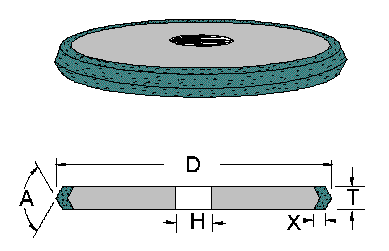

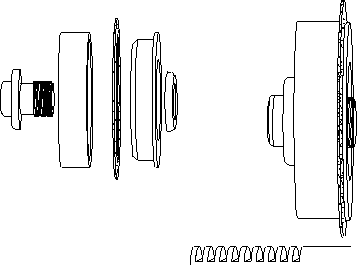

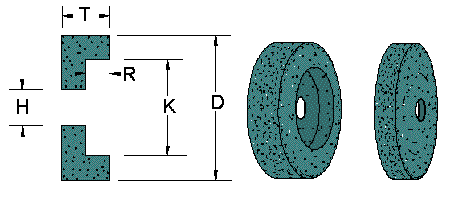

CBN resin bond wheels are engineered for high-performance grinding of hardened steels and high-alloy materials, delivering precise control over heat, surface finish, and edge integrity. The resin bond provides a fast, cool-cutting action that preserves the natural sharpness of CBN, making these wheels indispensable in tool grinding, production machining, and high-accuracy manufacturing. Because CBN does not chemically react with iron, it excels on ferrous materials such as high-speed steel, cobalt steels, tool steels, powder-metal grades, bearing steels, and nickel-based alloys. The controlled breakdown of the resin matrix continually exposes fresh CBN cutting edges, maintaining aggressive, efficient grinding throughout the wheel’s life. Resin bond also offers a natural cushioning effect, absorbing grinding forces, reducing friction, and minimizing heat-related damage such as burning, micro-cracking, and part distortion—especially important for thin edges and heat-sensitive geometries. These wheels consistently produce low surface roughness, excellent edge retention, and stable geometry, making them ideal for flute grinding, tool sharpening, form grinding, and fine-finish operations where tight tolerances are required. Their predictable wear characteristics ensure constant cutting sharpness, shorter cycle times, reduced dressing frequency, and consistent part quality in CNC machines, automated systems, and high-volume production environments. Advanced resin systems, including Braemar’s high-strength “Super Bond,” maintain form accuracy under high pressure, long grinding passes, and complex wheel shapes such as 1A1, 11V9, 12V9, and 6A2. Suitable for both wet and dry grinding, CBN resin bond wheels deliver maximum tool life and finish quality with coolant, while still performing well in lighter or lower-temperature dry operations.