Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

- Diamond Threaded Countersinks

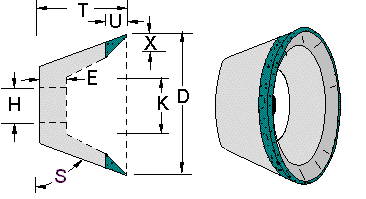

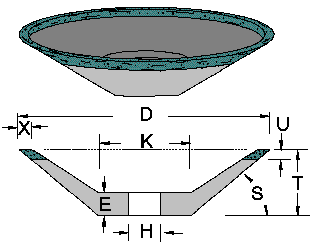

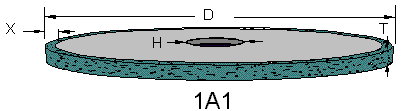

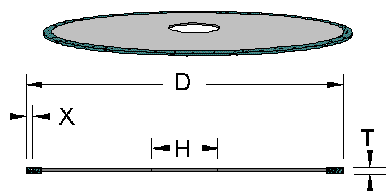

Monoset Diamond Wheels

Monoset Diamond Wheels are engineered for high-precision grinding applications that demand exceptional profile stability, sharp cutting action, and consistent surface finish. Built with controlled diamond concentration and a uniform bond matrix, Monoset wheels maintain geometry far longer than standard resin or metal bond wheels—making them ideal for CNC grinding, automated production lines, and ultra-tight tolerance grinding operations. Superior Form Accuracy & Geometry Retention Monoset wheels are specifically designed for environments where dimensional accuracy is critical. Minimal radius change during grinding Extremely low wear rate Perfect for profile grinding, form grinding, and multi-axis tool geometry Clean, Fast Cutting with Uniform Diamond Exposure The sharpened, consistently exposed diamond layer ensures: Lower grinding forces Cooler, more stable cutting Reduced chipping in brittle materials Clean edges and scratch-free finishes Reinforced Bond for Long Wheel Life Monoset wheels utilize a high-strength bond designed to resist: Loading Glazing Premature diamond pull-out This results in longer wheel life, stable performance, and reduced downtime. Optimized for CNC Tool Grinding & Automation Due to their geometry stability and predictable wear characteristics, Monoset wheels excel in: End mill & drill grinding Insert grinding Optical component shaping Ultra-precision finishing Applications Monoset Diamond Wheels are engineered for grinding: Tungsten carbide Technical ceramics Sapphire & quartz Glass & fused silica Carbide rotary tools PCD/PCBN tools (special configurations) Optical lenses, prisms, bevels, and edges Compatible with all major CNC grinders, manual tool grinders, optical machines, and precision finishing equipment.