Wheel

Diameter

(Inches)

|

Diamond

Size

Recommended

|

4-6

|

0.250 CT.

|

7-8

|

0.333 CT.

|

9-10

|

0.500 CT.

|

10-12

|

0.750 CT.

|

12-18

|

1.000 CT.

|

18-24

|

1.500 CT.

|

24+

|

2.000 CT.

|

|

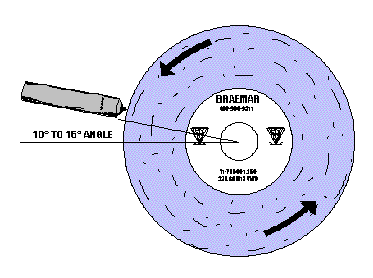

For the best and most cost effective dress, choose the correct size diamond for your job. See the chart to the left. To prolong the life of your diamond, follow the recommendations given below.

1. Store and handle with care. Diamonds are extremely hard, but also brittle. Store with diamond tip covered if possible.

2. Have tool reset when point is worn visibly dull and flat (.015 to .020 flat). Do not overuse the tool.

|

|

|

|

|

A new Single Point Diamond Tool

|

Correctly WornTime

to Reset.

|

Over Used

Diamond Damaged

|

|