Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

- Diamond Threaded Countersinks

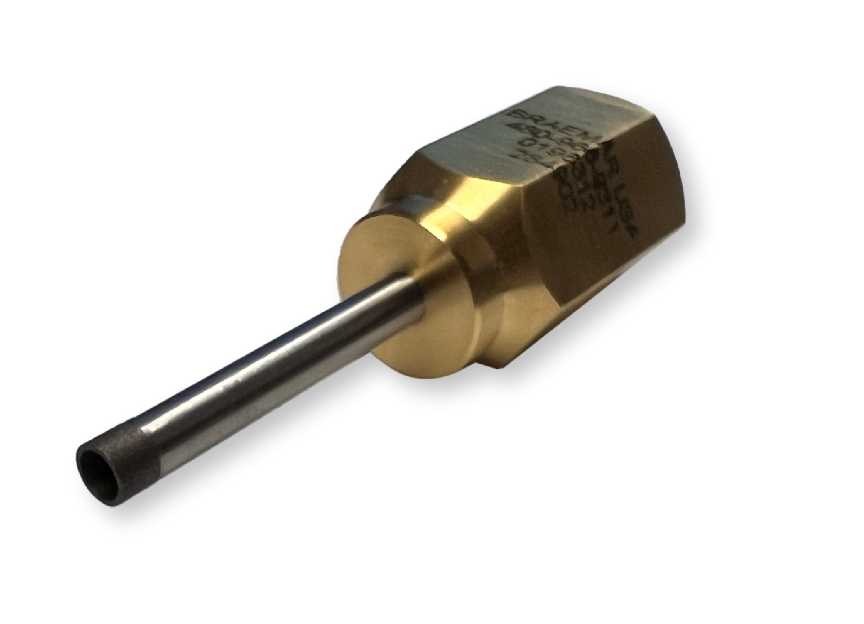

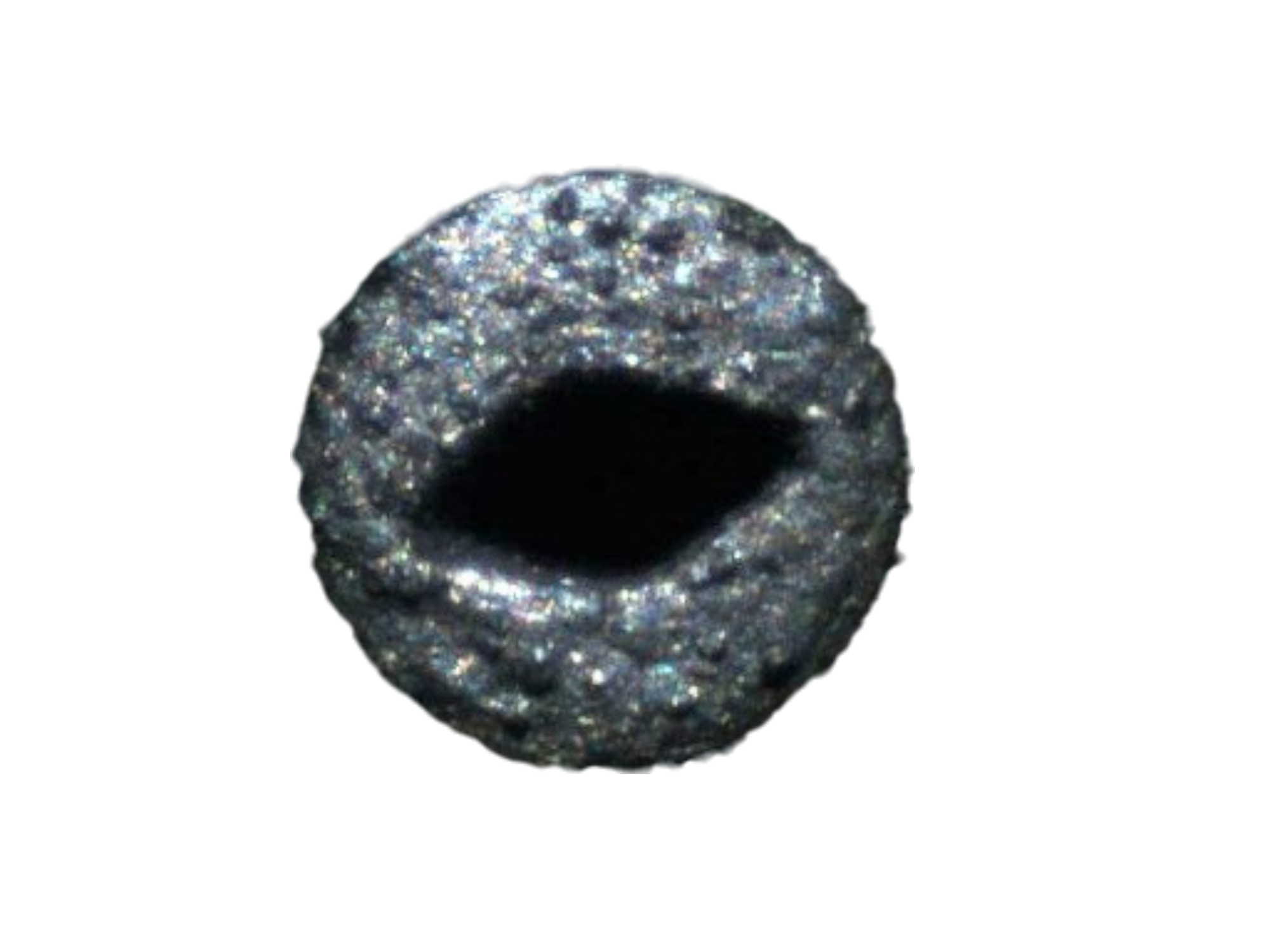

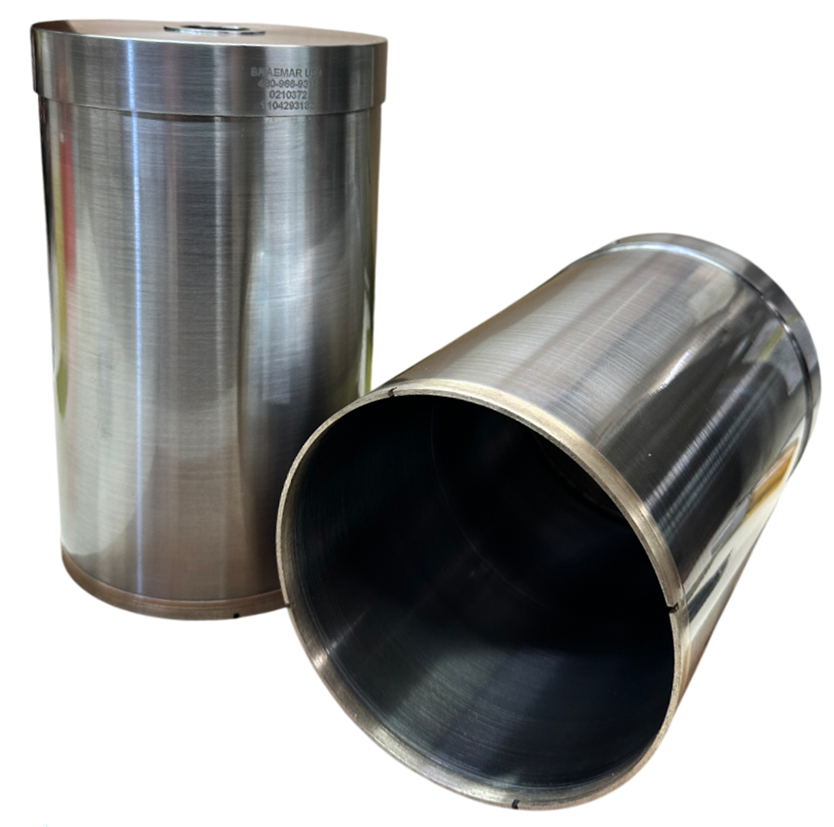

Diamond Core Drills

Braemar Diamond Core Drills Braemar USA designs high-accuracy drilling tools built to produce clean, consistent holes in demanding materials. Each drill features premium synthetic diamond and a carefully balanced bond system that supports stable, sharp cutting action from the first pass to the last. This construction helps create smooth edges, limit chipping, and maintain reliable hole geometry across production runs. Diamond Core Drills perform well on sapphire, quartz, ceramics, glass, carbide, composites, and a wide range of optical materials. They adapt easily to CNC platforms, ultrasonic equipment, manual setups, and laboratory environments. Their cool, efficient cutting reduces stress on the workpiece, minimizes micro-fractures, and extends overall tool longevity. Braemar USA also provides multiple bond formulations and structural options to meet different material and machine requirements. Choices include thin-wall barrels, strengthened designs, specialized geometries, and custom coolant pathways. Diameters, lengths, wall profiles, and abrasive grit sizes can be adjusted to fit exact specifications. Across sectors such as optics, semiconductor processing, carbide tooling, aerospace, medical manufacturing, and precision machining, these drilling tools offer the accuracy, durability, and surface finish needed for critical hole-making applications.