Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

- Diamond Threaded Countersinks

Diamond Ewag Wheels

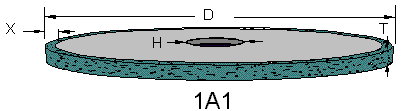

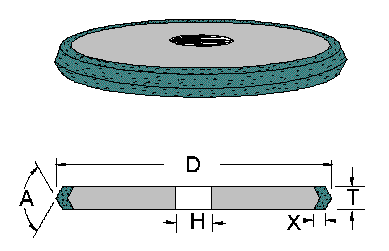

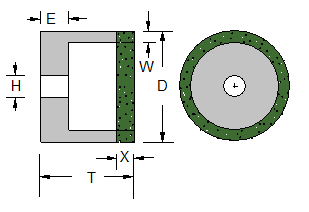

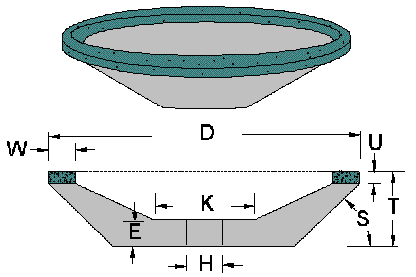

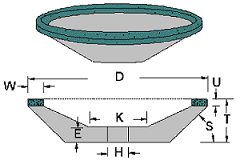

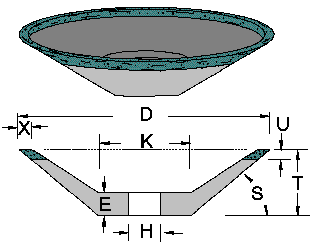

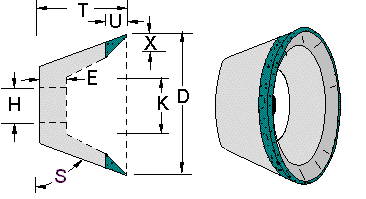

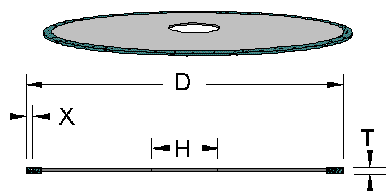

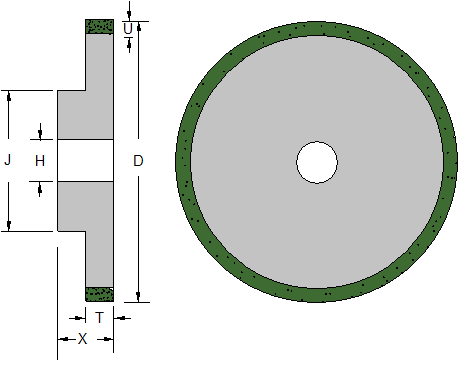

Braemar Diamond EWAG Wheels are engineered for ultra-precision grinding of carbide, ceramics, PCD/PCBN, sapphire, and advanced materials on EWAG tool grinding systems. Manufactured with premium synthetic diamond and tightly controlled resin bond and metal bond technologies, these wheels deliver exceptional surface quality, profile accuracy, and tool life for high-end CNC tool production. Designed to meet the exacting requirements of EWAG Ewamatic, WS11, WS11-SP, WS15, RS15, and other ultra-precision grinding machines, Braemar Diamond EWAG Wheels ensure consistent geometry, clean cutting performance, and minimal subsurface damage in demanding applications. Engineered for High-Accuracy EWAG Grinding Braemar wheels are manufactured to strict micron-level tolerances to support the full range of EWAG operations: Carbide blank grinding PCD/PCBN tool fabrication Radius and profile generation Fluting, clearance, and step grinding Fine-finish operations requiring scratch-free surfaces Our precision wheel construction maintains exact form throughout the life of the wheel—critical for contour grinding and multi-axis EWAG systems. Advanced Diamond Bond Technologies Braemar develops customizable bond systems optimized for EWAG production environments: Resin Bond EWAG Wheels Cool-cutting, free-cutting action Superior edge retention Ultra-fine surface finish quality Ideal for carbide, ceramics, and brittle substrates Metal Bond EWAG Wheels Longest life for heavy grinding loads High form stability Excellent diamond retention Perfect for PCD/PCBN tool production, wear parts, and ultra-hard materials Both bond systems are engineered to balance cutting speed, wheel wear, heat control, and accuracy—delivering consistent results across long production runs. Applications Across Precision Tooling Braemar Diamond EWAG Wheels support manufacturers in: Carbide tool grinding PCD and PCBN tool manufacturing Optics & precision ceramics machining Aerospace & defense component grinding Semiconductor and sapphire processing Automated CNC tool and cutter grinding From roughing to ultra-fine finishing, Braemar’s wheels provide reliable, repeatable performance in advanced tool production. Why Choose Braemar USA for EWAG Wheels? Engineered for tight tolerances and repeatable precision Available in resin, hybrid, and metal bond options Custom geometries for 11V9, 12V9, 14A1, 1EE1, 11A2, 1V1, and other EWAG shapes Optimized diamond concentration and grit sizing Superior wheel life and cutting efficiency USA-based engineering, support, and fast delivery Braemar ensures every EWAG wheel meets the dimensional accuracy and grinding performance required in world-class tool manufacturing.