Products

Shop our wide selection of products

Browse By Category

- Resin Bond Diamond Wheels

- Resin bond CBN wheels

- Electroplated Diamond Wheels

- Electroplated CBN Wheels

- Metal Bond Diamond Tools

- Diamond Core Drills

- Water Swivels

- Diamond Optical Tools

- Diamond Dressing Tools

- Diamond Bandsaw Blades

- Flexible Diamond Tools

- Information

- Monoset Diamond Wheels

- Diamond Ewag Wheels

- Diamond Lapping Compound

- Cutoff Wheels

- Diamond Threaded Countersinks

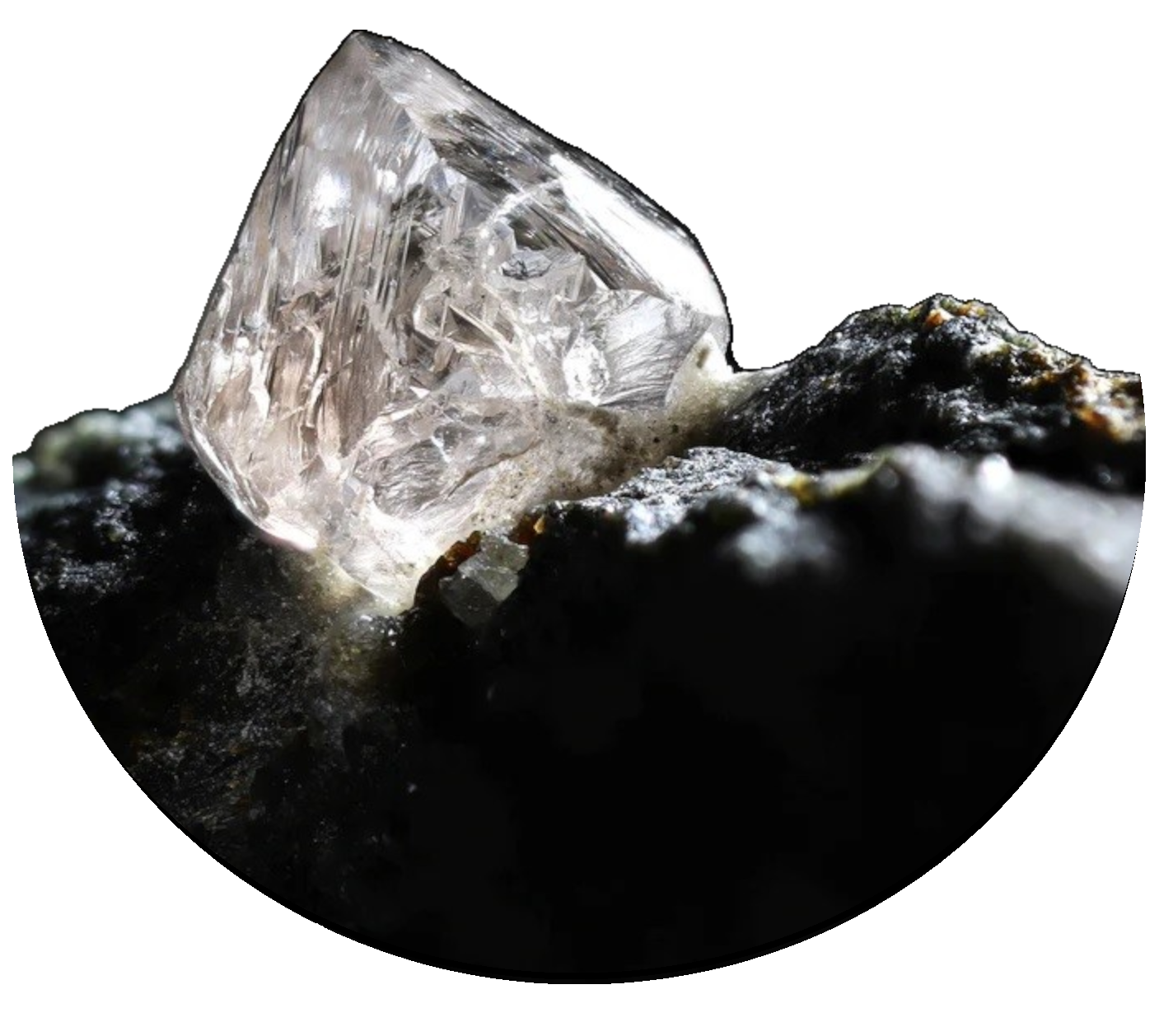

Diamond Dressing Tools

Diamond Dressing Tools for Advanced Grinding Braemar USA Diamond Dressing Tools restore wheel accuracy, geometry, and cutting efficiency. They use high-quality natural and synthetic diamond to deliver clean, consistent conditioning on carbide, ceramics, hardened steels, quartz, sapphire, and other advanced materials. Furthermore, whether you need a single-point dresser or a CNC form tool, Braemar provides stable, long-life performance you can rely on. Accurate Conditioning for All Wheel Types Braemar USA uses tightly graded diamond, controlled orientation, and precision-ground tool bodies for predictable results. Therefore, our Diamond Dressing Tools efficiently true and open resin bond wheels, metal bond wheels, vitrified wheels, CBN wheels, and conventional aluminum-oxide or silicon-carbide wheels. Additionally, each tool restores sharp abrasive exposure, improves cutting action, and enhances surface finish. Complete Line of Diamond Dressing Tools We offer a full range of dressing solutions for tool rooms and production floors. For example, our lineup includes single-point, chisel-point, and cone-point dressers. We also supply multi-point cluster tools, impregnated tools, Fliesen blades, form-rolling tools, radius dressers, CNC profile dressers, and fully custom designs. Moreover, these tools deliver smooth, controlled conditioning with low chatter and strong dimensional accuracy. Engineered for Long Tool Life Braemar USA designs every Diamond Dressing Tool for durability and steady performance. Because of their high diamond retention and uniform exposure, they maintain consistent wheel profiles over extended use. In addition, their strong shock resistance supports long production runs. Consequently, this reliability reduces downtime and improves both heavy stock removal and fine finishing processes. Industry Applications Braemar USA dressing tools serve industries where accuracy is essential. For instance, they support aerospace grinding, carbide and HSS toolmaking, optical lens production, ceramics and sapphire machining, semiconductor and MEMS manufacturing, automotive components, medical devices, and precision R&D environments. Ultimately, Braemar dressers deliver clean, repeatable results wherever tight tolerances matter.