SAPPHIRE TOOLING

|

Braemar manufactures metal bond diamond tooling for a variety of uses. We will design your tools to give you the best possible result. Since diamond tools are designed and used for many applications each tool reacts differently due to heat, pressure, machine, coolant, operator, etc. Sapphire is an extremely hard material that can dull a diamond tool quite rapidly. Using the correct bond along with the best possible diamond particles is necessary when grinding sapphire. We have developed a metal bond that will result is higher yields, faster feed rates, and increased productivity. Our "HPB" bond is used on tools that are 3.000" and smaller. This bond is very hard yet free cutting when grinding sapphire. Our "CPB" bond is used on larger tools, 3.000" and above. You will find that our HPB metal bond is extremely agressive and strong and will not crush or mushroom when pressure is applied.

|

CORE DRILLS

|

All of our diamond core drills are manufactured with our exclusive metal bond developed for high strength and longevity. Braemar can build your diamond core drills to suit your exact needs with a quick turnaround that today's industries demand. Our sizes range from .026" to 36" diameter with tolerance of (±.001") on 2" and under. We have the ability to mount core drills to your needs or the standard that is used at your facility. Braemar diamond core drills can be made with natural or synthetic diamonds, sieved to the desired grit size, mixed with a metal matrix and bonded to a steel core. The depth of diamond section is usually 1/4", or 3/8", other depth sizes can be made upon request. Diamond size can range from 60/80 to 270/320 grit. Coarser grit sizes are used for faster stock removal without much concern for surface finish.

|

GENERATOR RINGS

|

Braemar has been a leader in designing and manufacturing high-quality diamond wheels for most makes of optical surfacing and finishing equipment. Braemar diamond tools are engineered with thelatest bonding technology in use today. Braemar wheels cut lens material quickly, cleanly with minimal wear. Our precision aluminum hubs are balanced for optimum performance, while the light weight aluminum hubs are less demanding on your machines to help promote longer life. Special design laps cut to a special radius for optics, grinding and polishing of precision optics are available. Custom shapes are available such as grooved tools, tools with special threads, form tools, and other custom tooling. Diamond size can range from 60/80 to 3000 grit ( 4-8 micron ).

|

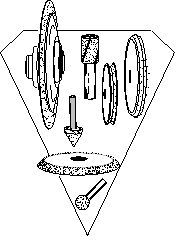

WHEELS

|

Braemar's diamond mounted and unmounted wheels can be manufactured in a variety of sizes and styles, both standard and custom to your specific forms and are designed for grinding sapphire. Braemar's Diamond Form Wheels can be manufactured to your exact needs. We can manufacture metal bond slotting wheels down to 0.004" wide. We can also provide flanges and adapters for single wheel and gang wheel applications. Our mounted wheels can be designed using carbide shanks for strength and rigidity. When you compare Braemar's performance, service and price of our metal bond products, you will find that our diamond wheels give you the value you have been looking for.

|